A few years ago, the 3D printing industry exploded onto the world stage. Now part and parcel of manufacturing parlance, it is proving somewhat of a divisive topic. We explore whether the hype was justified—and discuss some of the potential, issues and implications of which you need to be aware.

1. Not just a fad

It is only relatively recently that 3D printing has become part of mainstream discourse, but the technology has actually been around for many years. Back in the early 1980s, there were several attempts at enabling Rapid Prototyping—the beginnings of what we now know of as 3D printing. In 1986, Charles Hull became the first person to be issued with a patent for his stereolithography apparatus. Using the machine, Hull was able to convert digital data into a tangible, 3 dimensional object, using a laser beam.

An old 3D printer

Nowadays, there are a range of desktop 3D printers, apps, and software; anyone can have a go. But there has also been claims that the excitement surrounding the technology is not entirely justified. The general public is not able to print parts affordably; there are limits to the materials that can be used. Within industry use, techniques like CNC remain prevalent. The promised revolutionary changes to traditional manufacturing don’t seem to have followed through.

So does this mean that 3D printing is just another underwhelming technology fad?

Absolutely not. The fact that the technology is still capable of producing headlines simply demonstrates how far we are from realizing its potential. What it does mean is that we shouldn’t overestimate the performance of affordable printers, nor the skills (see more below) that are required. Even Autodesk have warned against the hype mentality—not to undermine 3D printing’s impact, but to explain the gap between expectation and reality. We are impatient, but it’s worth remembering that it has taken many years of behind-the-scenes activity to progress the technology to the point where it now lies; its longevity should not be in question.

Back in the early ‘80s, 3D printing was accepted as being the future. The reality, which all the developments since demonstrate, is that it is still the future now.

2. You can use the terms ‘3D Printing’ and ‘Additive Manufacturing’ interchangeably… though perhaps you shouldn’t

Traditional methods of manufacturing employ a subtractive technique, whereby excess material is cut away to form the required shape. CNC is an example of subtractive manufacturing. Additive Manufacturing (AM) works the other way round. It builds up layers of a material, fusing them together to create a product. Among other advantages, the process is designed to ensure less waste and more speed.

If that sounds like everything you’ve ever read about 3D printing, that’s because the terms are often used interchangeably. Whether or not they should be is a matter of some debate.

The official definitions laid out in ISO/ASTM 52900:2015 do differ. AM is regarded as the “process of joining materials to make parts from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing and formative manufacturing methodologies”.

3D printing, on the other hand, is deemed the “fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology”. This definition does carry the note: “Term often used in a non-technical context synonymously with additive manufacturing; until present times this term has in particular been associated with machines that are low end in price and/or overall capability”.

The definitions seem to bear slight different focuses: AM emphasizes the connection of materials, whereas 3D printing refers to the equipment used. This has led some to argue that 3D printing is a broader term, which can encompass—but is not exclusive to—Additive Manufacturing.

However, in practice, the word choice is largely down to perception. The media loves catchy phrases, and ‘3D printing’ sounds infinitely more exciting than ‘additive manufacturing’. Those in the industry may choose to call the process AM: possibly because it’s more specific, but also to sound a little more professional.

3. Moral implications

3D printed ovaries have allowed infertile mice to breed

One of the latest high profile cases of 3D printing was the successful production of healthy ovaries for mice. Infertile mice were able to conceive naturally following the procedure, which saw scientists print layers of latticed gelatin strips to form the ovary structure. They were designed in such a way that the blood vessels were able to fuse with those of the mice, and the tissue be accepted by their bodies. Healthy pups were born from the procedure; 3 litters were born of eggs produced by the printed ovaries.

The experiment sparked hope that in the future women with ovaries damaged by, say, cancer treatment, would be able to have them replaced with 3D prints.

But as well as the clear benefits of medical progress, there are also moral implications. The use of stem cells; the initial human trials, which may render participants ineligible for future, more sophisticated treatment; the designing of organs… all are issues that will need to be tackled.

At the other end of the spectrum, there is the potential for the production of items designed to cause harm. There was the instance, of course, of that gun. The images went viral, as did the widespread condemnation. And if 3D technology could be used to surpass gun regulations, it could also conceivably aid terrorists. Individuals could design and print their own parts for all manner of weapons, reducing risk of drawing attention to themselves.

But however unfortunate, the use technological advancements for harm is nothing new. All it means is that, as 3D printing progresses, so, too, will discussion and debate.

4. Out of this world

NASA have been an instrumental advocate of 3D technology. While others focus on its potential here on Earth, NASA have already taken a 3D printer out of its comfort zone (there’s one in the International Space Station) and are pushing the boundaries of the technology’s capability.

Way back in 2014, a team transmitted design instructions from Earth to the 3D printer in space, where it was able to produce a wrench. Having demonstrated successful use of the machine in a zero gravity environment, scientists are now taking things a step further.

One of the key challenges for designing in space is the limited resources available. However, a recent experiment has taken them one step closer to overcoming this obstacle. 3D printing with simulated ‘Martian dust’, made using samples of the real thing, has produced items made of a tough rubber, which has the potential to form tools and building blocks. Dust is abundantly available on both the moon and Mars. If and when colonization eventually occurs, NASA have proved the value of such a supply.

There is still some way to go; research must now begin into heating the prints in an effort to harden them. But these initial successes pave the way for more exciting times ahead.

5. Huge architectural potential

One of the areas with the greatest potential for utilizing 3D printing technology is, unsurprisingly, within the field of architecture.

Printed houses can be produced at a fraction of the normal cost; completed projects so far have reported impressive reductions in labour, raw materials and timeframe. Crucially, this helps to make them a viable prospect for building in the developing world.

The efficiency of the process also means that rebuilding homes, schools and hospitals in the aftermath of natural disasters might someday be a take a matter of weeks, rather than years.

There have already been several instances of 3D printed buildings. Apis Cor made headlines earlier this year when they managed to print an entire house on-site in under 24 hours. Situated in a Russian town, the house footprint amounts to 38m² and features curved walls and thermal insulation.

Image source: Apis Cor

3D printed houses like this might one day be commonplace

In addition to the production of life-size edifices, architecture firms can also take advantage of the impressive visual effects 3D printing affords. Along with Virtual Reality (VR), this technology is changing the way in which concepts and designs are presented to clients.

6. A 3D printer is not a 3D printer is not a 3D printer

With so many different types of 3D printing technologies available, it can be difficult to know where to start. Choosing a particular method of 3D printing largely depends on which material you’re working with and what your end goal is.

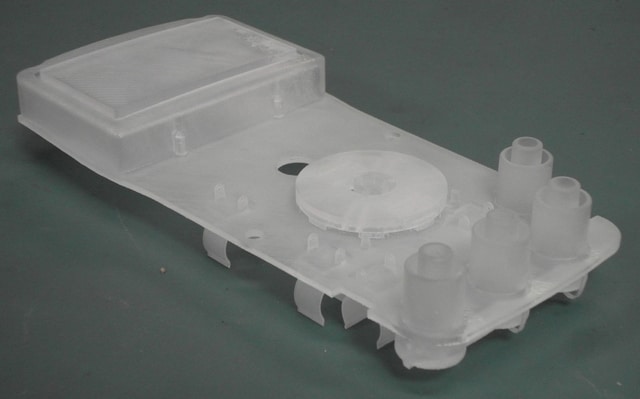

We’ve already mentioned Stereolithography (SLA), which uses a UV laser beam to harden liquid resin. Continuous Liquid Interface Production (CLIP) is a type of SLA under development. It uses an identical process, but is claimed to be much quicker, due to the presence of a special oxygen-permeable membrane on the resin, which aids the procedure. The smooth finish SLA technique is ideal for application where detail is essential.

This Printed Circuit Board has been made using SLA technology

Digital Light Processing (DLP) also uses a resin, but solidifies it using a projector, rather than ultra violet light. Lasers are, however, used (as the name suggests) in Selective Laser Sintering (SLS). Instead of resin, SLS requires materials to be in powdered form; these are then bound together. This method is versatile, and can accommodate materials from ceramics to steel.

Electron Beam Melting (EBM) also works with powdered metal. The electron beam is able to reach temperatures capable of completely melting the powder. Whilst this is useful for metals with high melting points, the technology needs work to make it more commercially viable.

Another of the most popular types of 3D printing is Fused Deposition Modeling (FDM). Cost efficient and ideal for prototyping, it works by heating plastic, which is then extruded horizontally. The object builds up as the print is lowered.

Wax Casting is officially known as Material Jetting (MJ). Instead of creating jewelry by hand, it is now possible to achieve the high level of detail necessary through nozzles, which deposits liquid wax in layers and leaves to harden.

Traditionally, making jewelry has required wax casting to be done by hand; the process may now be completed using a 3D printer

If you’re looking to 3D print in color, then Laminated Object Manufacturing (LOM) or Binder Jetting (BJ) are both good options. In LOM, pressure and heat cause laminates, coated in adhesive, to fuse together. When the layers are complete, the shape is then cut out. In a way, it could be described as both an additive and subtractive manufacturing technique.

BJ, on the other hand, extrudes a binding adhesive onto layers of powder. Previously criticised for lack of accuracy and ruggedness, there have been recent attempts to improve the technology, including by HP.

7. To do it well requires real skill

Thanks to the internet, public expectations of 3D printing are way beyond the capacity of the average Joe. Limitations to materials, accuracy of low-cost printers, and a lack of design knowledge are all factors in the discrepancies between what you see online and what you can create in the comfort of your own home.

In order to produce a high quality model, a good level of CAD skill is essential. Packages like AutoCAD and SolidWorks are ideal for this type of design. So where do you start?

If you’re a CAD novice, it’s worth checking out our introductory guides: you can learn the very basics of AutoCAD in just one hour. Or, if you’re new to SolidWorks, these tips and tricks will help you progress.

For those of you who already familiar with CAD design, it is a case of practice makes perfect. Task yourself with learning a new tool for every project—and if you get stuck, our sister site, CAD Answers, has… well, plenty of answers to assist you along the way.

So, 3D printing is likely to be more extensively used, but it isn’t—and will probably never be—appropriate for all manufacturing. In the meantime, there are plenty of us still needed for traditional CNC design. And that can throw up quite enough challenges of its own.