As years have passed by, a good number of CAD software has been developed. This has been due to the increment in the application of design in different fields of creation. These software applications created have a wide range of varying capabilities and as a result, there can be confusion when determining which software would be most appropriate for your specialty. At Scan2CAD, we assist by providing exhaustive explanations and comparisons of CAD software packages.

In this article, we would be giving a comparative description of two CAD applications; Creo by PTC Inc and CATIA by Dassault Systèmes. We would start by giving a brief history, then we would explore their various capabilities, users, and differences.

Table of Contents

Creo

This release of Creo is for sure one of the notable landmarks in the development of CAD. The journey of Creo started as far back as 1987 when PTC released Pro/Engineer which at that time was one of the first 3D CAD modeling applications. After years of improvement, Pro/Engineer was reborn in 2011 as Creo. Since the initial release date, there have been several versions. The latest, Creo 7.0, was released on the 20th of April, 2020.

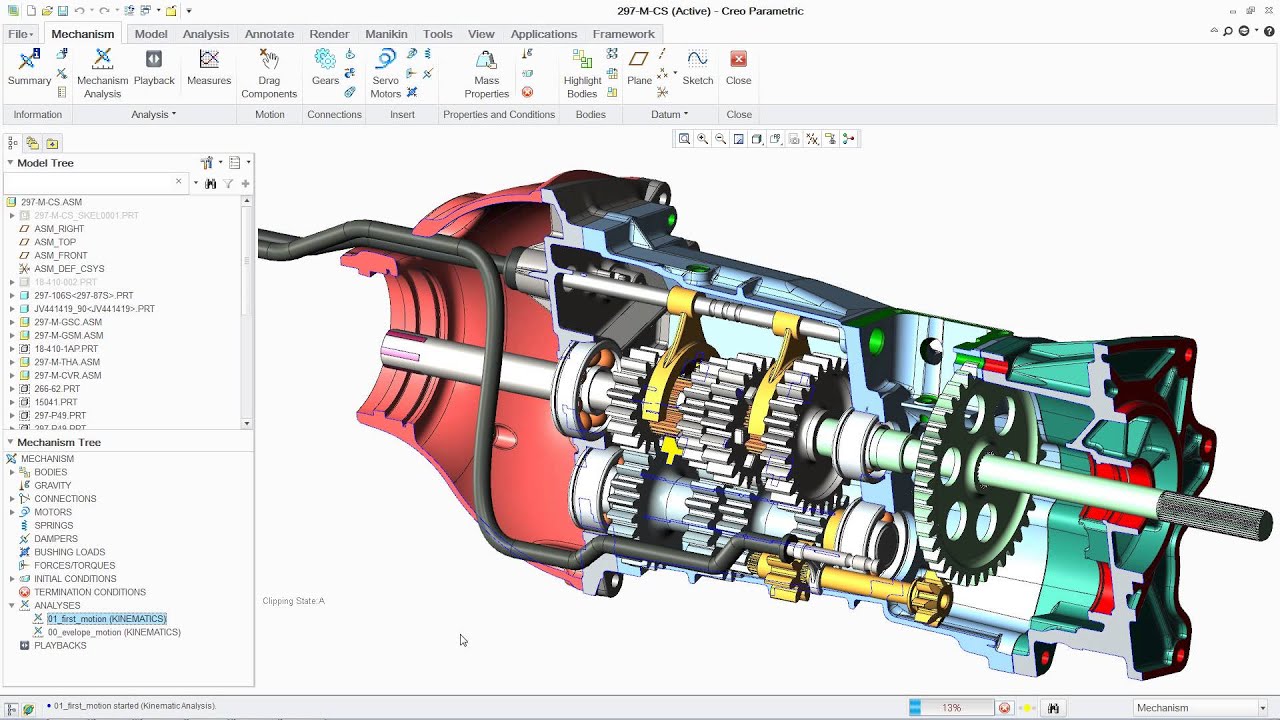

3D modeling in Creo (source)

What Does Creo Do?

Simply put, Creo is a collection of CAD design applications that offers features to help create designs for different industries. The software provides product design, manufacturing, and development capabilities. It offers modeling features for CAD, CAM, and CAE. Creo is compatible with Windows OS and is available in different languages. The software provides applications for 3D parametric feature-solid modeling, 3D direct modeling, 2D orthographic views, finished elementary analysis and simulation.

Creo has an impressive number of crucial capabilities. These features can be grouped into simulation and analysis, modeling and design, CAM, product data management, performance advisor, and technical illustrations.

Modeling and design

This feature enables you to create 3D models in a virtual environment. This is done using a direct modeling approach and the parametric modeling approach. In the direct modeling approach, you can pull and push directly on geometry, while in the parametric modeling application, where all the components are related, a change in one would lead to change in all.

Simulation and analysis

Creo comes with an interesting portfolio of simulation and analysis features. It helps in the analysis and validation of performances of 3D models The feature helps in;

- Thermal analysis

- Structural analysis

- Motion analysis

- Mold fill analysis

- Fatigue analysis

- Creepage and clearance analysis

Simulation and analysis features help avoid physical testing. Therefore, saving 30-50% of your design time.

CAM

Design for 3D printing can now be done without errors. Validation and optimization of your design, and carrying out a print check can all be done in one environment. With this feature, time, effort, and errors are substantially reduced. Creo has a great deal for designing machine parts for CNC manufacturing. The software’s effective tooling application can help you accomplish a great level of quality in a very short time. Creo CAM features can be classified as follows:

- Additive manufacturing

- Tool and die design

- Productive machining

Product Data Management

25% of most engineers’ time is lost due to their design’s data management. Time is wasted in the recreation of data, updating of systems, sharing of data and searching for files. Creo offers a cloud-based PDM feature that helps you manage, review and share data effortlessly.

Technical illustrations

This software’s feature permits you to create detailed 3D technical illustrations, animations, and 2D drawings. It also offers isometric viewings, CAD data re-use and CAD file conversations.

Who uses Creo?

Creo’s spectacular capabilities that answer to many aspects of product development makes Creo useful to many diverse industries. As Creo is a 3D modeling software for CAD, CAM, and CAE, mechanical engineers use it for modeling and analysis, civil Engineers use it’s simulation and analysis features for structural analysis, Designers in industries that provide information technology and services also make use of the software. Renowned companies have been known to use Creo. Few of many; Draper Inc, Astronics corps, Sterling Engineering Inc, Rheem Manufacturing Company, and FN America LLC.

CATIA

Previously known as CATI- Conception Assisté Tridimensionnelle interactive, french for interactive aided three- dimensional design, CATIA was founded by French manufacturer- Avions Marcel Dassault in 1977. Since the date of release, there have been significant modifications like the 3D market place that enables users of CATIA to connect with manufacturers. These improvements have continued until the release of its latest version, CATIA V5-6 released in 2019.

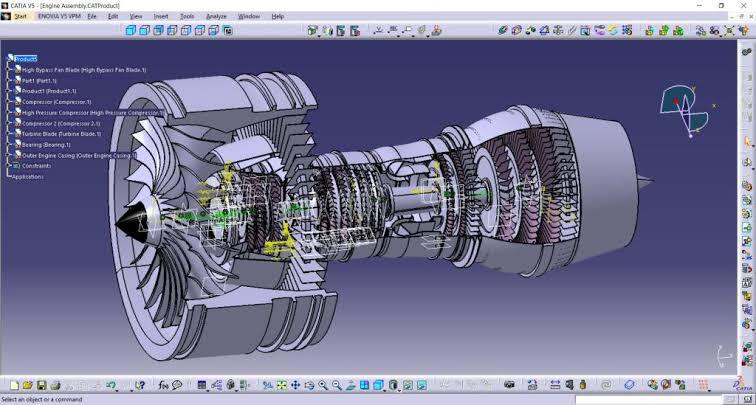

Modeling in CATIA (Source)

What does CATIA do?

CATIA is a collection of CAD applications for computer-aided design, CAD, CAE, and product life management.

CATIA has been able to provide tools to ease design in different engineering and design industries. The capabilities can be classified under Electrical systems, System Engineering, Mechanical Engineering, Fluid Engineering, and Design.

Electrical Systems

CATIA has provided electrical schematic definitions, requirement capture, and interactive 3D routing of both wire harness and industrial cable solutions in its CATIA V5 version. Proper synchronization of electrical schematics into 3D designs helps improve consistency and quality. Cost is also reduced as physical prototypes are avoided. This is because the design is done in the context of the full product.

Systems engineering

The software’s systems engineering solution offers an elaborate open development platform that wholly covers a wide range of disciplines. In modeling, simulation, verification and business process support.

Mechanical Engineering

The software supports the generation of 3-dimensional elements, 2D drawings, and sheet metal. Even in the world of aerospace, CATIA has a great deal for design.

Fluid Systems

Designing and manufacturing of routed systems such as tubing, piping, heating, ventilation, and air-conditioning (HVAC) have been made easy in CATIA V5. CATIA offers an environment for specification-driven design tools that make sure they are up to industry standard.

Design

The design tools in CATIA offer solutions for the design of complex shapes, surfacing workflow, styling, and visualization. These are done with the embedded ICEM surfacing technologies. Designers have been able to boost their creativity to produce designs of high quality and sophistication with CATIA.

Who uses CATIA?

CATIA’s myriad of exclusive capabilities makes the software useful to a wide range of diverse industries.

Mechanical engineers use it in the design of mechanical elements with a wide range of applications for tooling design.

CATIA has been able to help designers increase the quality of their designs using the proper tools provided by the software.

With CATIA Electrical, engineers use a 3D electrical development environment for the design of wire harness and cabling and also to acquire the exact diameters and cable lengths.

Fluid Engineers take advantage of CATIA’s generative and specification driven capabilities in the design of tubing, piping and HVAC systems.

CATIA is widely used in various industries such as aerospace, architecture, industrial equipment, shipbuilding, automotive, high tech, consumer packaged goods, energy process and utilities, and construction.

CREO VS CATIA

We have given an annotated description of Creo and CATIA. Now let’s compare the two software.

|

CREO |

CATIA |

|

The software is only compatible with Windows operating system |

Compatible with Windows and Linux operating systems |

|

Creo is easier to learn and operate |

More complex and has a steeper learning curve |

|

Creo’s license is subscription-based |

Offers perpetual licenses with yearly maintenance |

|

Products in the Creo suite are distinguished by their level of functionality |

Products in CATIA are distinguished by the industries they serve |

|

Creo’s license is less expensive |

The license is far more expensive |

|

It has to be connected to Windchill to have product life management features |

It comes elaborate product lifecycle management features |