The significance of computer-aided design (CAD) and computer-aided engineering (CAE) software in creating, verifying, and validating designs cannot be downplayed. Nevertheless, the utility of a tangible, solid model remains invaluable. In fact, tangible models help bridge the information gap by communicating design ideas visually to different teams within the manufacturing pipeline. These models not only capture the intention and ideas behind the design but also embody elements that would otherwise be left to the imagination. Rapid prototyping gives birth to these tangible models, especially early on in the manufacturing process or in small-scale manufacturing.

Rapid prototyping is fundamental in evolving a design from concept to physical product. It achieves these through a variety of techniques that constitute the various types of rapid prototyping. In addition to discussing these types, this article will capture the rapid prototyping definition, how it compares to conventional manufacturing, and explore the applications of the process. Let’s get started.

Table of Contents

Understanding Rapid Prototyping

What is Rapid Prototyping?

Rapid prototyping (RP) refers to a group of techniques used to fabricate a scale model of a part or assembly through a one-step layered manufacturing process in a short amount of time. Also known as Solid Freeform Fabrication (SFF), rapid prototyping relies on horizontal cross-sectional data from a 3D CAD model, typically created using CAD/CAE software. The rapid prototyping machine begins by laying a thin layer of material following the outline of the bottom-most cross-section of the model. Once it completes this bottom-most layer, it moves on to the next layer and repeats this process until the part is complete.

RP traces its roots to the 19th century when techniques such as photo sculpture and topography were utilized. However, the modern version of RP – what exists today – was invented in the 1980s with the birth of 3D printing. Since then, technology has evolved, giving rise to numerous techniques, which constitute the various types of rapid prototyping (discussed below).

It should be noted that, while related, rapid prototyping and additive manufacturing (AM) are not identical concepts. RP, along with 3D printing, is a subset of AM. For its part, AM refers to technologies that create 3D objects one layer at a time. It relies on computer-aided manufacturing (CAM) software or 3D scanners to control machines that deposit material, layer by layer, following a predefined path, thus creating precise geometric shapes. For the avoidance of doubt and according to the ISO/ASTM rapid prototyping definition, RP is a subset or application of additive manufacturing that seeks to reduce the time taken to produce prototypes.

Rapid Prototyping vs. Traditional Manufacturing

RP differs from conventional manufacturing primarily due to its emphasis on speed. While the latter comprises multiple steps, including design, material handling setup, process planning, production planning, quality control, and inspection, rapid prototyping involves one single step: constructing the part or assembly. This way, RP saves production time and cost.

A second point of distinction emerges when both processes are analyzed vis-à-vis their areas of application. While conventional manufacturing is confined to the manufacturing industry, the term rapid prototyping is also utilized in other sectors. It is also used in the development of computerized systems. Software developers use RP to describe the process of developing and testing a business or software product more quickly than conventional methods. They utilize RP to optimize usability, assess time and cost, and its ability to solve customers’ issues. That said, this article confines itself to the definition used in the manufacturing industry.

Applications of Rapid Prototyping

There are seven main uses of rapid prototyping, namely:

- Design evaluation

- Verification of models’ functions

- Generating marketing ideas and obtaining customer feedback

- Serving as an additional manufacturing process

- Medical applications

- Bioengineering applications

- Rapid prototyping in art

Prototypes for Evaluating Designs

Physical or tangible models solve a number of problems encountered when dealing with virtual models displayed on a computer monitor. They, for one, eliminate resolution-based limitations that could hinder observation. It is widely recognized that the human eye possesses unmatched resolution. It cannot be compared to even the most advanced monitor technology. Thus, the monitor’s resolution, inferior to the human eye’s, limits the quality of designs and models developed using CAD/CAE systems. In contrast, a tangible model does not suffer from such a limitation, meaning you, as the observer, get to see or view everything in full resolution.

Secondly, a physical model enables teams to analyze and evaluate the potential cost of manufacturing the product. If, upon assessment, the calculated cost is deemed to exceed the allocated budget, then the design team modifies the design. Alternatively, the manufacturing team might alter the manufacturing processes.

Thirdly, RP can create sectional views of a model. Gone are the days when the prototype had to be created whole and then cut to show the internal structure. Nowadays, using RP, you can print a sectional view.

Prototypes for Verifying Functions of Models

Let’s consider that you are working with an assembly that is naturally made up of several parts. Using rapid prototyping, you can create each of these individual parts as a body of a complete assembly. This approach negates the need to assemble the individual parts. If these parts are supposed to move relative to each other as in kinematic models, then you can conduct mobility analysis. Therefore, RP enables you to verify the functioning of the assembly.

In addition, you can also conduct other tests, including fatigue strength, hydro- or aero-dynamics, or stress/strain analysis. Results from these tests can be correlated with those generated by CAE software. And given that these tests are done immediately after production, rapid prototyping significantly saves production time. Overall, this approach also cuts costs.

Prototypes for Marketing Ideas and Customer Feedback

Once a product has been manufactured, it needs to be marketed. Usually, a good marketing campaign is well thought out and results from plenty of brainstorming sessions. To facilitate marketing, prototypes can be provided to the relevant teams well in advance of final production, allowing ample time for the development of marketing ideas. Similarly, the prototypes can be delivered to clients to assess their reception and even seek feedback on how to improve the designs.

Rapid Prototyping in Manufacturing

Rapid die casting and rapid plaster molding are quick and economical ways of creating dies and molds. Specifically, models created by rapid prototyping are used as templates or patterns for manufacturing molds and dies. This way, RP supports tooling for other forms of product manufacturing. However, when it comes to the mass production of functional products, CNC machining is typically preferred over rapid manufacturing. For instance, once the design and manufacturing teams have arrived at the final layout and iteration of the molds and dies, these products are mass-produced using CNC machining.

Rapid Prototyping in Art

RP can be applied in a number of ways in various fields of art. These include:

- Creation of props

- Utilizing 3D printing to create tangible models of virtual art

- Reproduction of degraded or lost historical relics in museums

Rapid Prototyping in Medicine and Medical Applications

RP can help simplify otherwise complex aspects of the medical field. Specifically, it helps medical practitioners create models that they can then base their training or rehearsals on. Broadly speaking, the medical applications of rapid prototyping include:

- Fabrication of 3D anatomical models of the skull and other body parts, assisting surgeons in planning and rehearsing complex surgical operations, such as maxillofacial and craniofacial surgeries

- Fabrication of precise replicas of different organs and body parts for education and research

- In the dental space, RP models can be used to design orthodontic treatment equipment that fits each patient’s tooth alignment

Rapid Prototyping in Bioengineering

Rapid prototyping applications in the bioengineering space include:

- Creation of scaffolds of complex tissue structures to support growing stem cells as part of tissue engineering

- Fabrication of customized prosthetics and implants

- Implementing 3D organ bioprinting

While research is still ongoing, experts reckon that organ bioprinting may help doctors print organs such as kidneys using cells from the patient instead of having to find a donor match. These artificial organs imitate natural organs. Billed as the future of organ transplantation, organ bioprinting represents a significant advancement. It utilizes 3D printing technologies to layer multiple biomaterials, growth factors, and cell types, thereby producing bioartificial organs.

Types of Rapid Prototyping

The various types of rapid prototyping include:

1. Stereolithography

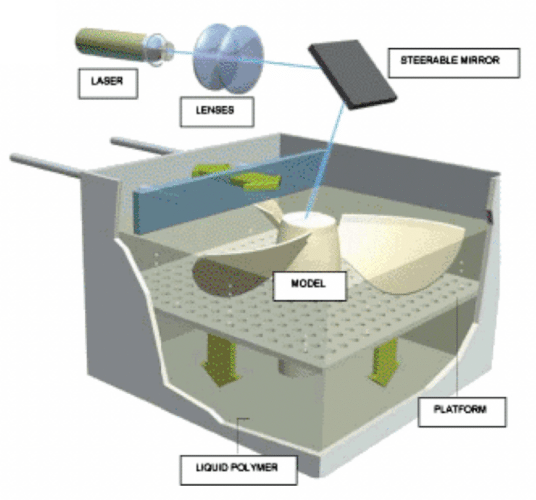

Stereolithography is the liquid-based rapid prototyping process of making solid objects using a liquid photosensitive polymer that is cured by computer-controlled ultraviolet rays. The polymer fills a bath that covers a platform that can be lowered or elevated. At the onset of the prototyping process, the platform is elevated to rest just a layer’s thickness below the surface of the liquid polymer. By shining UV light following a predefined pattern, the first layer of the model is formed. Thereafter, the platform is lowered by a length equivalent to the thickness of the layer. This process is repeated until the fabrication is complete.

Illustration of the Stereolithography RP Method

Moreover, just as there are micromachining processes, rapid prototyping supports the microfabrication of parts using micro-stereolithography.

2. Fused Deposition Modeling (FDM)

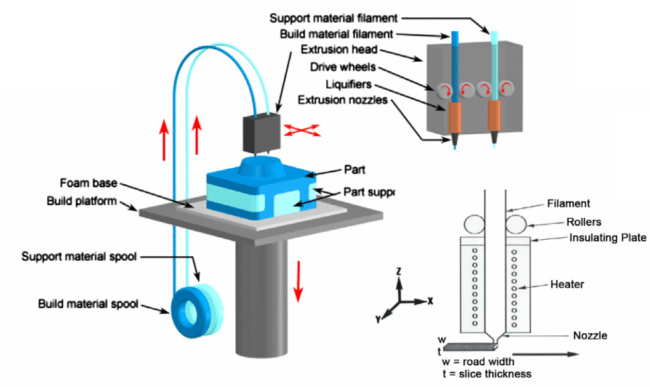

In fused deposition modeling or FDM, thermoplastic material is heated and extruded through nozzles. CNC controls these nozzles’ movements. The nozzles, capable of controlling the flow of material, deposit the melted substance layer by layer. The material hardens immediately upon extrusion. FDM is used in most consumer-grade 3D printers and is an example of a solid-based rapid prototyping technique.

Illustration of the FDM RP Method

3. Laminated Object Manufacturing (LOM)

In laminated object manufacturing (LOM), layers of metal, plastic, or paper laminates coated with adhesives are bound together and subsequently cut to shape. Unlike other types of rapid prototyping, models created by LOM require additional modification. Typically, additional processes such as drilling or other machining techniques are required.

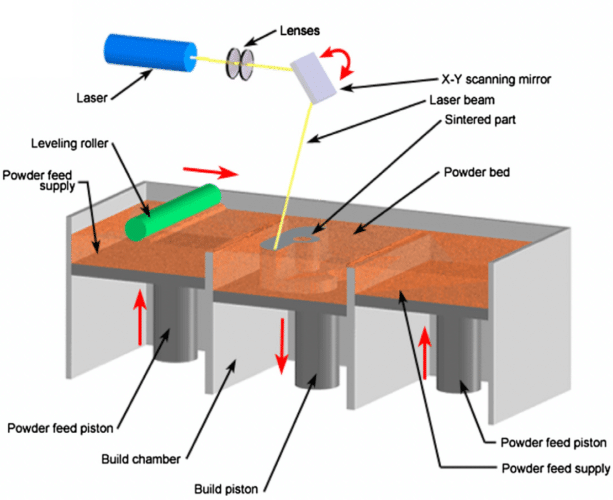

4. Selective Laser Sintering

Selective Laser Sintering (SLS) is a powder-based RP process. Here, a layer of material is introduced, with a computer-controlled laser drawing a cross-section of the part to sinter (heat without melting to bond the particles) the powder particles. This process continues in a cycle until the rapid prototyping machine finishes fabricating the part.

Illustration of Selective Laser Sintering

5. 3D Printing

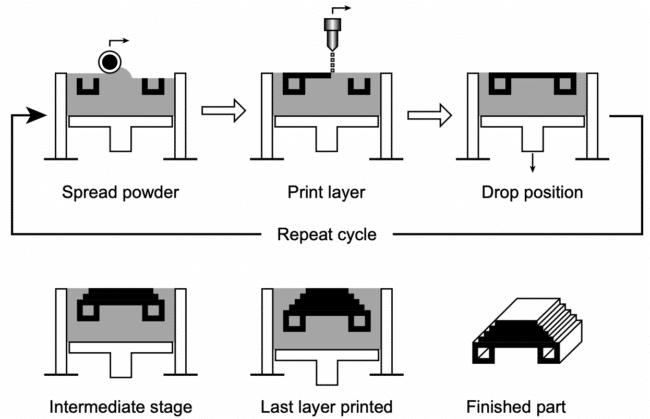

Like SLS, 3D printing is also a powder-based rapid prototyping process. Here, the machine deposits a layer of powder; it then extrudes a binder solution in a controlled fashion, with this solution bonding the powder to create the cross-section of the model. The unbonded powder remains loose and helps support the subsequent layer. The machine repeats this process until fabrication is completed.

Illustration of 3D Printing Rapid Prototyping Process

6. Solid Ground Curing (SGC)

Solid Ground Curing (SGC) uses a photosensitive polymer to produce prototypes. It works by exposing a layer of the polymer to a UV lamp through a mask. The mask prevents light from reaching certain predetermined sections of the polymer’s surface. The UV light cures the resin, hardening it. The uncured resin is vacuumed out, and wax is poured to fill the void left by the vacated materials. The cured material forms the layer on which the subsequent layer will be poured and cured. This process is repeated until the prototype is completed.

7. Ultrasonic Consolidation

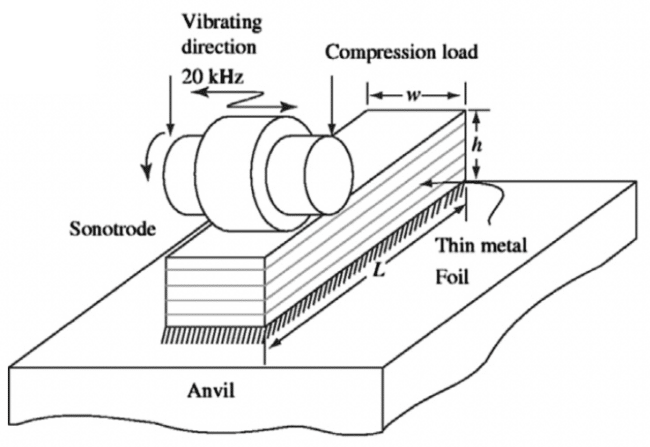

This rapid prototyping method creates models by ultrasonic vibrations to weld sheet metal laminates together. As soon as a layer of build material bonds to the preceding one, CNC milling is deployed to shape the internal and external boundary contours.

Illustration of Ultrasonic Consolidation Rapid Prototyping Process

8. Electron Beam Melting (EBM)

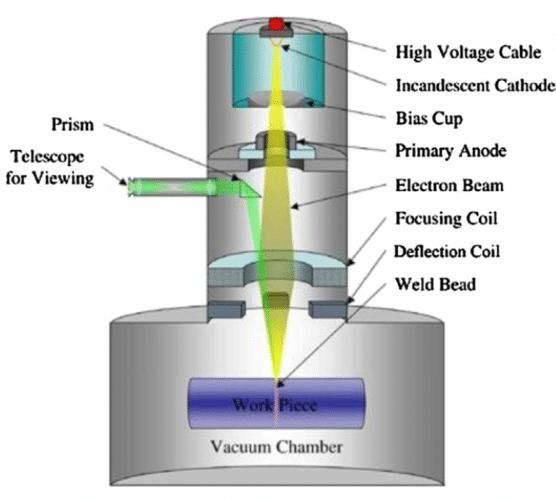

Electron beam melting (EBM) produces titanium parts in hours rather than minutes. It uses an electron beam to melt titanium powder. The melted material solidifies to form the first layer. The process is then repeated, forming the subsequent layers. EBM is growing in popularity due to its capability to produce dense parts with exceptional strength-to-weight ratios. Moreover, it is faster and cheaper than other additive manufacturing processes.

Illustration of EBM Rapid Prototyping Method

9. Laser-Engineered Net Shaping (LENS)

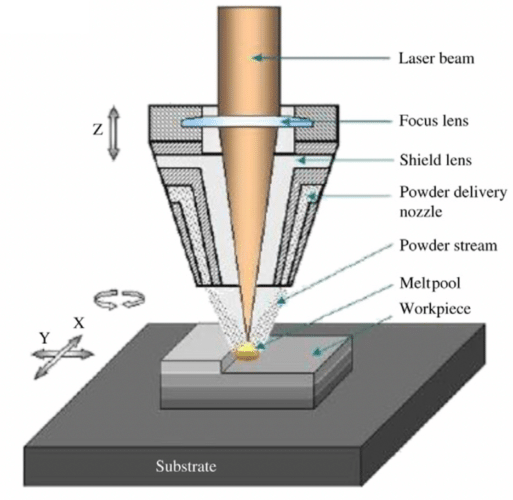

As the name suggests, LENS utilizes lasers. These computer-controlled lasers weld air-blown streams of metallic powder, creating parts. It is mainly used to create high-density molds or parts. Also, parts produced using this rapid prototyping process bear shapes that are as close to the final product as possible. Thus, LENS eliminates the necessity for further machining processes often required in other RP methods.

Illustration of LENS Technology

(Note: the illustrations have been sourced from the book ‘e-Design: Computer-Aided Engineering Design’ by Kuang-Hua Chang)

Advantages of Rapid Prototyping

Rapid prototyping offers the following advantages:

- It reduces the lead time for manufacturing both simple and complex parts

- Rapid prototyping facilitates substantial cost savings in production

- It does not require tooling, as it follows the same layering process to create a model

- This process does not require manufacturing process planning

- Rapid prototyping produces physical products that communicate design ideas to professionals within the manufacturing chain, including machinists, customers, and more

- It allows the incorporation of customer feedback into subsequent iterations of prototypes

- RP produces both concept and production models typically in one day; in fact, rapid prototyping methods such as EDM can fabricate parts from hard materials such as titanium, taking up less time than other AM processes

- Rapid prototyping is extremely precise and, thus, reduces wastage

- The rapid iteration enables teams to quickly solve any problems, reducing or eliminating the risk associated with such errors at later stages of manufacturing

Limitations and Challenges of Rapid Prototyping

While advantageous in many ways, there are a few limitations of rapid prototyping, including:

- Some rapid prototyping methods, such as LOM, require material removal by machining, which is an additional step

- Manual cleanup is necessary to remove excess powder or unwanted material

The Role of CAD in Rapid Prototyping

The use of CAD, CAE, and CAM software is contextually known as virtual prototyping. As discussed earlier, this software has certain observation limitations that may hinder the observers’ ability to visualize designs or models. Additionally, the software can affect how well a designer can communicate their ideas with other parties in the manufacturing chain and clients. For this reason, rapid prototyping is used, as it solves these issues.

However, despite its shortcomings, virtual prototyping is extremely instrumental to the success of rapid prototyping. In fact, without the data generated by CAD software, rapid prototyping machines cannot create any decipherable part. This is because the machines rely on the cross-sectional data stored in the virtual 3D model to produce the tangible parts layer by layer. The use of CAD makes the rapid prototyping process extremely precise. It also helps reduce the amount of waste generated.

Moreover, the software, specifically CAM software, generates programs that guide the movement of the machines. Additionally, the programs outline the material flow rate, layer depth, whether or not to create support materials, and more. Without this information, rapid prototyping machines would not create precise geometrical shapes. Moreover, they would not be able to create exact representations of the virtual models. Put simply, CAD and CAM, which store data that defines the geometrical parameters of concept models, enable rapid prototyping machines to create physical products from this concept data.

Conclusion

Rapid prototyping is a group of techniques that includes laser-engineered net shaping (LENS), electron beam melting (EBM), ultrasonic consolidation, 3D printing, solid ground curing (SGC), stereolithography, fused deposition modeling (FDM), laminated object manufacturing (LOM), and selective laser sintering. Since its inception in the 1980s, rapid prototyping has revolutionized the product development arena, notably reducing costs and lead times, and crucially enabling teams to produce rapid iterations of products. As a subset of additive manufacturing, it is deployed in a myriad of areas, including manufacturing, medicine, bioengineering, design evaluation, and more. But none of these use cases would have been possible without CAD software.