Computer Numerical Control (CNC) machining is a popular manufacturing approach because it is extremely accurate, safe, and flexible. It also allows manufacturers to create complex shapes. Moreover, it can be deployed in mass production, as it creates uniform products. However, the accuracy and precision vary based on the type of machine. With the market filled with numerous manufacturers, each with its own offerings, choosing the right CNC machine for your business can be intimidating. We have, therefore, compiled this guide to help you make the right decision. That said, this article is not intended to recommend a particular supplier or suppliers. Instead, it aims to provide you with as much information as possible, equip you with the knowledge, and help you choose a CNC machine – the best machine, in fact – for your business.

Table of Contents

Types of CNC Machines

There are nine main types of CNC machines, namely:

1. CNC Router Machines

CNC Router (source)

CNC routers are primarily designed to cut soft materials like wood, foam, and plastic. That said, some specialized routers can also cut soft metals such as aluminum. CNC router machines only work with soft materials because they have less torque – they use rotational speed to cut through materials. As such, they do not have enough power to cut hard materials.

In CNC router machines, the material lies stationary on the bed/table while the router head moves across the three axes, as in 3-axis CNC routers. (The router head houses a rotating router bit.) Some router machines are capable of additional movements. These are known as 5-axis routers. Typically, a 5-axis machine allows movement or rotation around 5 CNC machine axes: three linear axes (X, Y, and Z) and any two of the three rotary axes (A, B, and C). A rotates around the X-axis, B rotates around the Y-axis, and C rotates around the Z-axis.

The advantages of CNC router machines include:

- They are fast and offer great productivity

The disadvantages of CNC router machines are:

- They are less accurate than some other CNC machines

- CNC routers are limited to working with soft materials

2. CNC Mill Machines

CNC Mill Machine (source)

A CNC mill machine is a high-precision machining tool that can work with hard materials such as aluminum, steel, and even titanium. It is capable of making more delicate cuts than a router machine. In addition, CNC milling machines can be used to shape, bore, and drill metal. To achieve various milling operations, the machines utilize different types of cutters (mills), including end mills (e.g., ball nose end mills and bull nose end mills), fly cutters, and face milling cutters.

This type of CNC machine also differs from the CNC router in another way. As indicated above, the workpiece in a CNC router remains stationary while the router head moves across the various axes. However, in CNC mill machines, the spindle head moves along the X- and Y-axes while the workpiece moves along the Z-axis. It is worth noting, however, that the cutting action is produced because of the cutter’s rotating motion. The moving workpiece contributes to the CNC mill machines’ increased precision.

The advantages of CNC mill machines include the following:

- They can work on hard materials

- CNC mill machines offer great precision, with some accounts noting that they can make cuts to within thousandth of an inch

- They support numerous operations, including shaping, boring, drilling, and cutting

- CNC Mill machines are suitable for mass production as they guarantee consistency and quality

The disadvantages of CNC mill machines are:

- They can be costly

3. CNC Lathe Machine

CNC Lathe Machine (source)

CNC lathe machines are primarily used to create cylindrical or round shapes. They are used for machining parts through a cutting process. Usually, the part or material is radially affixed to a rotating platform, which rotates it at a predetermined RPM. The cutting tool, on the other hand, moves laterally at a feed rate measured in inches per revolution. The cutting tool can also move inward or outward, thus altering the thickness of the material.

The CNC lathe machine is ideal for creating parts that should have the same symmetry around a given axis. In addition, it can be used to perform several operations, including threading, boring, drilling, reaming and facing (cutting across the end – face – of a part).

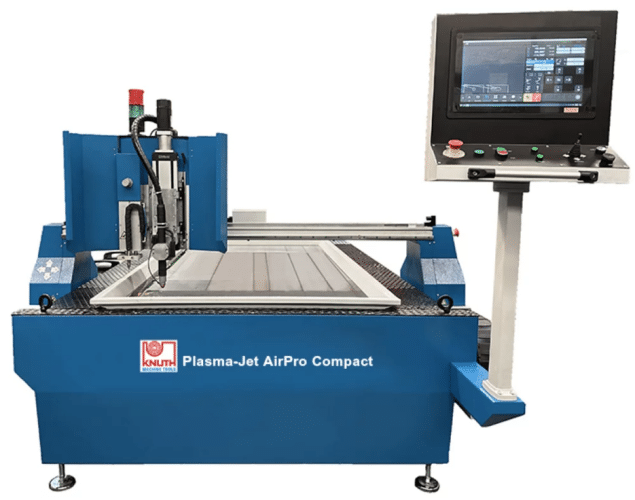

4. CNC Plasma Cutting Machine

CNC Plasma Cutter (source)

A CNC plasma cutting machine injects an electric current into a compressed stream of air or gas (such as argon, nitrogen, oxygen, or hydrogen), creating a high-energy, electrified gas that is passed through a nozzle. This causes the air/gas to squeeze through at high speed, forming plasma. (Plasma is the fourth state of matter in which charged particles comprising a combination of electrons and ions exist.) It is this plasma that melts the metal, essentially cutting it. However, the heat generated can be disadvantageous, as it modifies the region adjacent to the cut boundary.

There are three types of CNC plasma cutting machines based on the cutting process, which include:

- High-frequency contact: This low-budget process poses a risk to modern equipment and is, therefore, not used in CNC plasma cutters. It uses a high-frequency spark (which forms when the plasma torch contacts the cut metal, closing the circuit) along with a high voltage. The closed circuit creates the plasma that is used for cutting.

- Pilot arc: This second process combines a high voltage and a low current circuit to create a spark within the plasma torch (rather than outside). When the plasma cutter contacts the metal or workpiece, it creates a cutting arc, after which cutting can begin.

- Spring-loaded plasma torch head: This process relies on the creation of a short circuit when the torch is pressed against the metal and the release of this pressure, which establishes a pilot arc.

The CNC plasma cutting machine can be used to cut aluminum, stainless and mild steel, copper, brass, or cast iron. Essentially, it can cut any metal that conducts electricity. However, this can be a limitation, as it only cuts conductive materials. Beyond this, it offers a number of advantages, including:

- It produces high-quality cuts

- The CNC plasma machine is fast, being faster than laser cutters when cutting thick metal sheets

- It offers high precision

- The machine can be used in situations that require repeatability. This is particularly true when cutting thick metal sheets due to the associated speed.

This type of CNC machine has a few disadvantages, including:

- It is noisy

- The CNC plasma cutting machine produces fumes

- Some of its components, such as the nozzle and electrode, require periodic replacement

- It is unable to cut extremely thick materials.

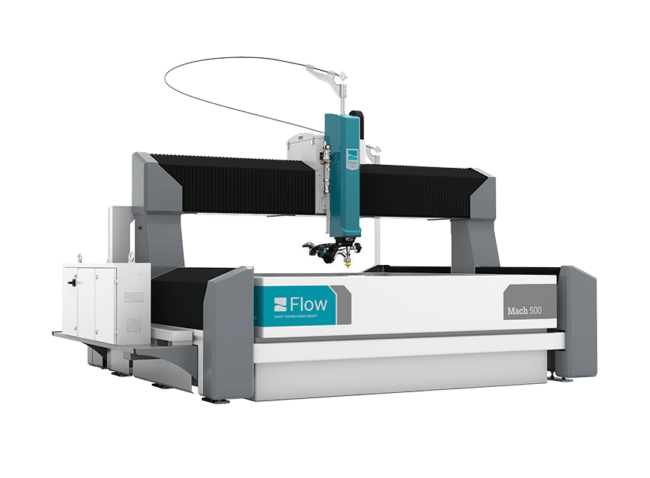

5. CNC Waterjet Machine

CNC Waterjet Machine (source)

The CNC waterjet machine uses a CNC-directed vertical waterjet to cut materials such as titanium, paper, foam, marble, glass, and ceramics. However, when cutting hard materials, abrasives are added to the water stream (after it exits the nozzle) to enhance the cutting power. Generally, this machine produces clean cuts without burn marks or burrs (irregular rounded masses). While it is primarily used for cutting operations, the CNC waterjet machine can be deployed in a few other areas. For example, using multiple rotating waterjets, the machine can be used in paint stripping and surface preparation operations.

CNC waterjet machines offer several advantages:

- They do not leave water behind, even when used to cut absorbent material. This is due to the velocity of the water.

- They produce clean cuts without burn marks or burrs

- The waterjet does not produce heat, which means they do not introduce mechanical stresses, surface hardening, or propagate cracks

- The water can be reused repeatedly, as the method does not pollute the fluid

- It can slice a moving slab of material

There are several manufacturers of CNC waterjet machines, including Flow International Corporation, which sells the Mach line-up of products. Others include Techni Waterjet™ with its Intec™ G2 Waterjet CNC machines and Knuth’s Waterjet B-series machines, just to name a few.

6. CNC Laser Machine

CNC Laser Machine (source)

CNC laser machines are used to either cut material or mark parts. These machines work in one of three ways. The first involves the CNC program directing the laser over the surface of the material. The second involves the program moving the platform’s axis that carries the material, with the stationary laser beam. This movement defines the shape of the cut material. The third utilizes computer-positioned mirrors that direct the laser to the material – neither the laser nor the material moves. These mirrors move in three axes, expanding the working envelope without necessarily increasing the machine’s footprint.

The energy produced by the laser beam can be varied. In this way, CNC laser machines can be used to remove material from only a fraction of the surface. Or, they can extend the cutting to great depths. Other advantages of the CNC laser machine include:

- They produce little heat-impacted zones due to the narrowness and intensity of the laser beam

- These machines are highly accurate

- They are quiet

- When used to mark parts, they produce fast and permanent marking

- CNC laser machines offer excellent sheet utilization.

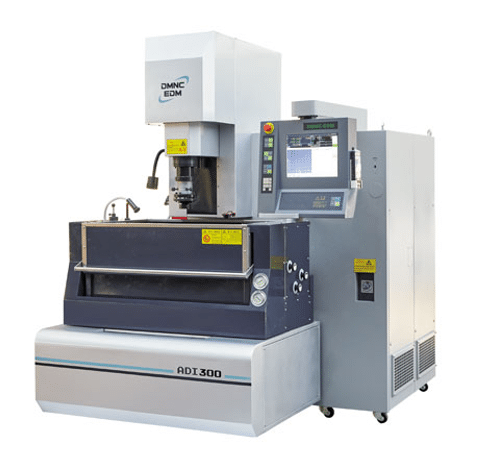

7. CNC-Driven Electrical Discharge Machine

CNC-Driven Electrical Discharge Machine (source)

Electrical Discharge Machining (EDM) is a metal-cutting technology. It is used in cases where the target shape is impossible to achieve using other processes or where the metalwork is too hard to machine conventionally. It is also selected when a mirror finish is required. These machines cut metal by generating millions of tiny electric arcs between the workpiece and the electrode. These arcs act as the ‘cutting teeth,’ vaporizing and melting the metal, creating microcraters. The melted particles cool and are immediately flushed away, as the metal is submerged in a fluid. Besides washing away waste, the fluid, which is a dielectric, also provides a cooling effect and controls the cutting process, thus promoting accuracy.

The advantages of a CNC-driven electrical discharge machine include:

- It produces a mirror finish

- The machine can cut any metal regardless of the hardness

However, there are a few concerns that are worth taking into account when it comes to this type of CNC machine. This can be summarized as the disadvantages of CNC-driven EDMs:

- The heat produced can modify the material

- The depth of the cut decreases the flushing ability of the fluid. In fact, the particles of the metal, the destroyed electrode, and the burned fluid build up within the gap

- As the cutting action progresses, the energy spread increases over the expanding area, reducing the arcs’ temperature to a less-than-useful level.

8. CNC Grinding Machines

CNC Grinding Machine (source)

CNC grinding machines utilize a rotating wheel that removes material from a metallic workpiece. They produce very high-quality surface finishes and are, therefore, mostly used during the finishing stages of the machining/manufacturing process. This surface finish quality depends on the grinding wheel’s speed, which should remain constant throughout the process. Therefore, the motor should be capable of delivering the required torque consistently and reliably. Additionally, since the process generates a lot of heat, a lubricant is used to cool the workpiece’s surface.

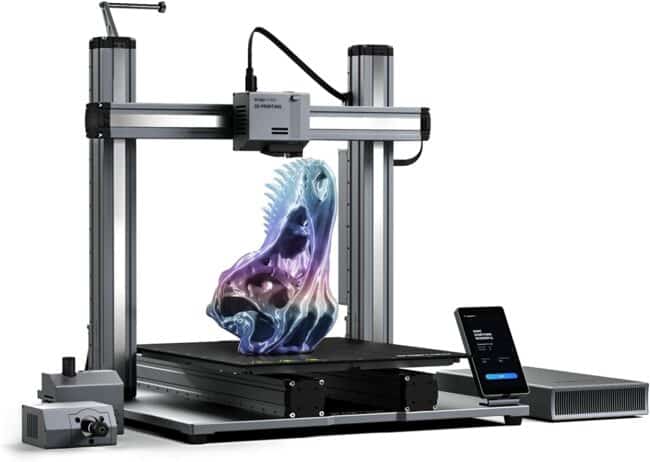

9. 3D Printer

3D Printer (source)

3D printing is an example of CNC machining. However, it differs from all the other types of CNC machines above, which use subtractive manufacturing. 3D printing is an additive manufacturing process that relies on the G-code programming language to guide its movement. It involves melting and extruding material, such as resin or metal, layer by layer to create physical shapes from a digital 3D model or CAD file.

Factors to Consider When Choosing a CNC Machine

Choosing a CNC machine can be daunting. However, we have compiled a list of ten factors to consider whenever you wish to make this crucial decision.

1. Motor Power

The motor drives the cutter in CNC mills and lathe machines and the grinder in grinding machines. Therefore, when choosing a CNC machine, consider whether its motor can deliver the power for the intended task. For instance, if you intend to use your CNC router to smooth the edges of wood products, then a lower horsepower machine will suffice. In contrast, a higher horsepower machine is better suited for more extensive jobs.

Additionally, consider whether the motor power is supplied by hydraulic pumps or electric current. Hydraulic motors generally offer more power, durability, and efficiency than electric motors. As a result, they are primarily used in precision CNC grinding machines.

2. Type of Drive Motor Used

CNC machines use motors to drive movement along or around the various axes. The motors should be capable of moving the same way every time upon receiving a given amount of energy. The acceleration and deceleration curves should also be similar. However, not all motors have these properties. In this regard, the type of drive motor should also be a prime consideration when choosing a CNC machine.

There are three types of drive motors: the servo motor, stepper motor, and hydraulic motor. The hydraulic motor is driven by pumps but is less common. The servo motor is highly controllable; it delivers predictable speed, power, and acceleration curves based on the input energy. As the input energy increases, this type of motor exerts more force or spins faster. DC-driven servo motors are the most common and are preferred in heavy machining. Servo motors require tuning for proper system operation.

Moreover, they are generally more expensive than stepper motors. However, these factors should only concern you if you are building a CNC machine; if you purchase a ready-made CNC machine, the manufacturer will have already tuned the motors.

Lastly, as the name suggests, the stepper motor moves in small increments based on the energy received. This type of motor requires computation as the CPU must coordinate the timed input of energy, measured in pulses, with the programmed feed rate. The faster the pulses are sent to the motor, the faster the motor rotates. Stepper motors are best suited for woodwork or detailing work. That said, they are cheaper and simpler to understand and work with; moreover, they do not require tuning.

3. Material

Two related but fundamental questions you should ask yourself are: What material will you be using? What will you make? This is because CNC machines are suited for different functions. For instance, say you are into woodwork; the kind of machine you would use to mill furniture parts is very different from the one you would use to carve signs. It is evident that wood has significantly different properties from metal. Thus, if you are looking for a CNC machine best suited for milling or cutting metal, avoid selecting a CNC router. Instead, choose other options such as the CNC mill machine, CNC plasma cutter, or CNC laser cutter.

4. Budget

Different manufacturers cater to different market segments, developing and selling CNC machines for various price points. It is important to note that sub-$1000 CNC machines are not suitable for commercial use. Instead, these machines are designed for hobbyists. Thus, if you need a CNC machine for your business, consider choosing a slightly more expensive machine designed for commercial use.

Additionally, the prices of CNC machines vary based on the technology used and the capabilities. For instance, the Fab Light laser cutter for sheet metal and tubes starts at $65,000. On the other hand, the Trulaser 3030 2D laser cutting machine, which boasts high performance, high-speed cuts, and is much larger than the Fab Light machine, costs north of $1 million, according to one YouTuber. Moreover, the Tormach 1100MX CNC mill starts at $26,975, despite being slightly larger than the Fablight machine.

TruLaser 3030 CNC Laser Cutting Machine (source)

Conversely, entry-level CNC plasma machines, suitable for small welding shops, are priced around $18,000 (£15,000). Industrial plasma cutters cost between $113,000 (£90,000) and $315,000 (£250,000).

5. Size, Work Capacity, and Production Volume

Some CNC machines, especially those designed for mass production of parts, have a large footprint comparable to a small car or SUV. In addition, in some cases, machines such as laser cutters require additional equipment such as an air compressor, auxiliary air tanks, a compressed air dehumidifier, and a dedicated dust collection and air filtration system. Thus, before you choose a CNC machine, ask yourself whether your workshop is large enough to house all this equipment.

And if the workshop is large enough, is your production volume commensurate? Large CNC machines are intended for mass production. Thus, if you want to choose a CNC machine that will help you iterate prototypes and produce products faster, then a large machine with all the necessary tools is desirable. This is due to their continuous duty rating. However, the size also impacts the price. For instance, the Trulaser 3030 2D laser cutting machine, which is larger than the Fab Light machine, costs north of $1 million, according to one YouTuber. It, however, boasts high performance and high-speed cuts.

On the other hand, if you choose a machine with a small footprint, it is equally important to consider the usable area. The machine should not be so small that it prevents you from accomplishing the tasks or working on certain sizes. Therefore, when selecting a CNC machine, look for terms like ‘working envelope,’ ‘work zone,’ and ‘usable area.’ These terms define the exact area within which the cutting tool can operate.

6. CAD/CAM Software

Most consumer-grade CNC machines come with a CAD/CAM program included or available as an option. Still, you do not need to worry about the program that comes with the machine. Most CAM software, such as Fusion, SolidWorks, CATIA, BobCAD, and more, are compatible with most CNC machines.

However, some manufacturers, such as CarveWright and ShaperTools, maintain a closed ecosystem, developing proprietary systems that are intended to control the toolpaths. This, therefore, means you have to learn how to use such software, adding unnecessary steps to the manufacturing process. Occasionally, these programs are only accessible by paying a subscription fee. Thus, when looking to choose a CNC machine, consider whether it can be operated by third-party software or if the software is free.

7. Cutting or Machining Technology

Indeed, there are different types of CNC machines, each using its own cutting or machining technology. As highlighted above, these technologies are suited for different materials and produce different results. In addition, some cutters, such as CNC waterjet machines, can be used not only to cut material but also to strip paint and prepare the surface. Others, like CNC mills, can be used to drill, bore, and shape metals, while CNC lathe machines can be used for threading, boring, drilling and reaming, and facing. Thus, you should consider the machining technology as it opens you up to multiple other operations beyond cutting.

8. Nature of Control (PC or Handheld Control)

Some CNC machines, like the Shaper Origin from ShaperTools, are handheld. This means they assign you, the user, the responsibility to manually steer the machine as it makes the cuts. Nevertheless, these machines have intelligent features that compensate for human errors. For instance, the Shaper Origin makes real-time adjustments to ensure clean cuts. Also, if you steer outside the programmed path, the machine’s spindle automatically and safely retracts.

Shaper Origin Handheld CNC Router (source)

On the other hand, other CNC machines, their cutting tools, and their movements are 100% controlled either via a control system on your personal computer or through the software installed on the machine itself. The latter category operates without requiring a PC connection. But this convenience comes at a cost, as this type of CNC machine is often more expensive than PC-based machines. This is due to the fact that they have a built-in computer and storage that handles the computing tasks. A PC-controlled CNC machine example is the CNC Shark by Rockler. On the other hand, the Axiom Precision line-up of machines and some Fanuc-, HAAS-, and Bridgeport-branded CNC machines do not require a PC connection; they come with controllers or control panels.

9. Online Forums

Like all other mechanical components and software, CNC machines and systems can sometimes be problematic and complicated. Fortunately, reputable manufacturers have online forums that allow users to share experiences, ask questions, and receive answers to queries. These online communities are valuable resources for gathering real users’ opinions, which can help you compare machines. Additionally, they can help you familiarize yourself with the machines’ workings.

10. Operator Skill Level

The CNC machines function quite differently, meaning the operator has to learn how each machine works. The knowledge gained while working with a particular type of CNC machine may not apply to another, especially if it is manufactured by a different manufacturer. Nonetheless, to get around this problem, machinists can use the same universal CNC controller for each machine.

Manufacturers such as Fanuc sell a wide range of CNC control systems. This line-up includes systems for standard machining applications to those capable of handling the most complex machining processes. These systems are compatible with CNC machines produced by other manufacturers. So, you can consider purchasing a universal CNC control system.

Fanuc’s Line-up of CNC Control Systems (source)

Choosing a CNC Machine Supplier

Even with the tips above, choosing a CNC machine and a supplier can be intimidating. This is because there are multiple options in the market. And given that the machines are expensive, going with the wrong one poses a significant monetary risk. Therefore, it pays to take time before deciding to choose a CNC machine and supplier. This calls for a strategic approach that follows the following six tasks or activities:

1. Research and Compare Different Suppliers and Offerings

Of course, there are multiple suppliers of each of the nine types of CNC machines. To stay ahead of the competition, these manufacturers promise various offerings, including after-sale services, features, and tools. Thus, if you hurriedly choose one supplier, you might eventually find out that you got a raw deal. We, therefore, advise that you carry out extensive research, utilizing both online and offline resources. Next, compile a comprehensive list of the different suppliers and their offerings. Using this list, you will then be able to compare these manufacturers and what they have to offer.

2. Evaluate Supplier Support and Training Resources

A simple look at the various suppliers’ sites shows a glaring difference: they have different approaches to offering support and training. For example, most offer learning materials in the form of in-depth training classes and courses on metalwork or woodwork, how-to resources, project ideas, step-by-step explanations of the features of the CNC machines (product training), and more.

At the same time, the suppliers offer support quite differently. For example, most usually staff their support team with field technicians (factory-trained employees) who have first-hand experience and can help clients with all service needs. This approach enables them to fix incidents via phone calls without having to dispatch technicians. As a result, downtime is minimized, especially given these individuals are available round the clock, 24/7.

However, you may be surprised to realize that some suppliers do not provide supplier services – at least, that is what we gathered by extensively going through their websites. (We cannot mention names, though.) For this reason, it is crucial to choose a CNC machine supplier that promises 24/7 support. After all, the mechanical equipment is bound to break down at one point during its service life.

3. Check Customer Reviews and References

As a business operator or owner, you may know a few other businesses that operate in your specific sector. And even if you do not, you can always create rapport by reaching out and asking about their preferred CNC machines. Armed with such information, you can easily choose a CNC machine over another. Alternatively, you can go through customer reviews on social media or dedicated review sites like Trustpilot. However, reviews are hard to come by because industrial-grade machines are rarely sold online but rather by directly contacting the manufacturer or supplier.

4. Go Through Online Forums

Online forums are convenient platforms where customers share their experiences with the manufacturers’ CNC machines. They also ask questions about problems encountered during use, expecting answers from other users or the company’s representative. Therefore, these online forums, which are maintained by the manufacturer, are an ideal way to gather data on problematic machines. This way, you can identify those to avoid, thus helping you narrow down your search.

5. Evaluate After-Sale Services

Some suppliers – such as FANUC and Flow Shape Technologies Group – work on the premise that every customer’s needs differ. They, therefore, adapt their after-sale services to suit these specific needs. As a result, they offer predictive, preventive, and reactive maintenance, as well as a comprehensive catalog of OEM parts.

Preventive maintenance involves undertaking scheduled maintenance after a given number of hours or months. Predictive maintenance entails remotely monitoring the condition of your equipment to determine when the supplier should schedule the maintenance. This approach predicts breakdowns before they can result in downtime. Lastly, reactive maintenance involves scheduling repairs immediately after the equipment breaks down, with the work carried out by local OEM-trained service engineers.

Some suppliers only offer some of these services, while others offer all. However, the latter is predicated on selecting and paying for the maintenance package containing all these services. So, if you want to enjoy all these perks, choose a CNC supplier who promises these offerings and subscribe to the service.

6. Negotiate Fair Price and Warranty Terms

Once you have arrived at a few viable options of equal quality and caliber, it is time to purchase. It is nonetheless important not to rush into it. Instead, contact the suppliers and negotiate a fair price and warranty terms. But the likelihood of a successful negotiation is dependent on multiple factors. It goes without saying that these suppliers have dealt with big-name clients. So, exercising patience, deploying soft negotiations, and showing what you bring to the table is crucial.

Assessing Machine Performance and Maintenance

Unplanned downtimes can be expensive. Automotive companies, for instance, lose an average of $22,000 per minute when the production line stops. For smaller manufacturers, this figure is likely smaller. Still, data shows that the average manufacturer suffers 800 hours of equipment downtime every year or over 15 hours per week. This downtime is often attributed to reactive maintenance processes, where companies wait for the equipment to break down before they can repair it. However, predictive and preventative maintenance has been shown to keep production running and improve uptime. So, how can you achieve maximum uptime and productivity?

1. Monitor Productivity

It is important to establish the baseline performance. Once a machine’s productivity falls below this figure, it can be said to be performing under par. This can point to a developing problem, helping you predict and prevent future breakdowns. In fact, some suppliers who provide predictive maintenance services use this approach. They connect their servers to the machine, collecting and monitoring data on its performance over time and the performance history throughout its lifecycle. This data enables them to identify issues and speedily resolve them.

2. Identify Common Maintenance Issues and Costs

By assessing the machine’s performance history, you can gather information about common maintenance issues and the associated costs. You can then use this data to purchase the required spare parts. By having a catalog of parts, you can replace those that break down as soon as they stop working, allowing you to reduce downtime. This data also helps you allocate a budget for repairs or maintenance, ensuring you are always prepared for any eventuality.

3. Evaluate the Need for Additional Software or Hardware Upgrades

It is advisable to consider an upgrade, especially if adding certain software or hardware can help improve performance or the maintenance procedure. For instance, a combination of software and hardware upgrades could enable you to collect data remotely, assisting in predictive maintenance. However, first, conduct an in-depth assessment to establish whether it is a worthy investment. After all, such upgrades can be extensive.

Conclusion

There are multiple types of CNC machines, some of which can be an excellent fit for your business. These include CNC router machines, CNC mills, CNC plasma cutters, CNC waterjet machines, CNC lathe machines, CNC laser machines, 3D printers, CNC-driven electrical discharge machines, and CNC grinding machines. Coupled with the presence of numerous supplies, this wide variety of viable options makes the act of choosing the right CNC machine daunting and intimidating. In this guide, we have highlighted factors to consider when choosing a CNC machine, approaches to use when selecting a supplier, and how to assess machine performance and performance to boost uptime.