The manufacturing industry is pursuing miniaturization, driven by the demand for high-accuracy miniaturized products that comprise tiny features or normal-sized products with tiny features. This demand is not sector-specific, as it is found in the automotive, biomedical, aerospace, electronics, and communication industry. To quench this demand, precision micro-machining has emerged. However, more often than not, the mention of micro-machining brings to mind the idea of miniature parts.

While the argument behind such an idea is sound, it is inaccurate because the term has nothing to do with the size of the parts.Instead, as we will explore below, it relates to the fabrication of miniature features on parts of any size. Perhaps more specifically, it involves the use of innovative methods and tools to achieve the desired level of accuracy and precision. This article explores what micro-machining is, compares it to conventional machining, discusses various micro-machining processes, and provides an overview of the systems, tools, and equipment used in micro-machining, as well as its applications in different sectors and industries.

Table of Contents

Understanding Micro-Machining

What is Micro-Machining

From a less technical standpoint, micro-machining, also written as micromachining, can generally be used in reference to the process of machining features that are too small to be machined by conventional machining processes. However, looking at the process from a technical perspective that considers the literal meaning of micro, which means the millionth of a unit, in this case, the meter, the definition takes on a new form. In this context, micro-machining involves the use of subtractive micro-tools and techniques to fabricate features with at least one dimension ranging from 1 micrometer (µm) to 999 µm. This means the diameter of the tools’ cutting edges measures 1 µm to 999 µm.

However, the International Academy for Production Engineering Research (CIRP), which helps standardize technical terminology, notes that the micro/macro border is sometimes set at 500 µm. (This figure is, however, not cast in stone, as it varies based on the machining method used.) In that case, the range of micromachining is said to primarily vary between 1 µm and 500 µm. To further prevent ambiguity, the CIRP defines three criteria that subtractive processes, especially mechanical processes, must obey to be considered micro-machining methods. These include:

- The processes must use a tool whose diameter ranges between 1 µm and 500 µm; the sizes of the features must also fall within this range

- The undeformed/uncut chip thickness (a measure of the tool penetration depth or the amount of material the tool removes) must be the same as the workpiece grain size (the estimated average diameter of a grain of a metal or alloy)

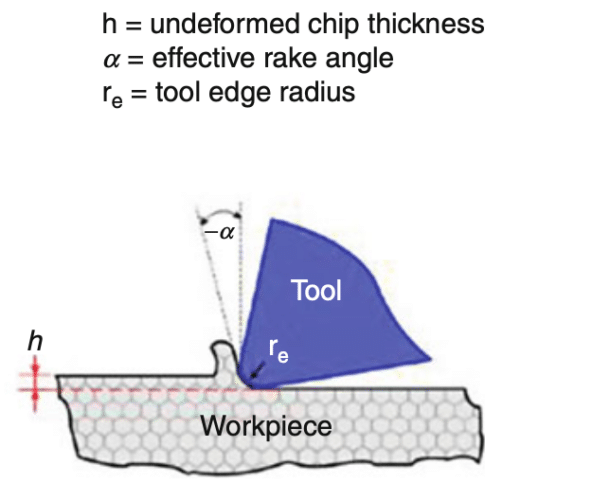

- The undeformed chip thickness and the workpiece grain size must be in the nanoscale range to a few micrometers in length and comparable to the tool edge radius

Schematic Representation of Undeformed Chip Thickness (Source: CIRP)

Micromachining vs. Conventional or Macro-Machining

The miniaturized scale of tools used in micromachining gives rise to issues not readily encountered in conventional machining. One primary issue is the possibility of tool breakages. This is especially prevalent in contact tool-based micromachining processes that require the exertion of some degree of force by the micrometer-scale tools on workpieces. Other technically constraining factors include surface integrity, shape complexity, and machinability. However, there are different types of micromachining processes. Some are designed to remove material without the tool contacting the workpiece. Others can be combined to achieve the designed finish to machine extremely hard materials – this has given rise to hybrid machining.

Nevertheless, micromachining offers numerous benefits over conventional machining. Thermal micromachining methods, for instance, consume less energy, as the machines require less voltage and current to operate than conventional machining systems. Moreover, micro-machining achieves high accuracy and precision. Hence, it heralds a new era of precision manufacturing. Micromachining also achieves better surface finishes, although in some cases, this depends on the usage of extremely high spindle rotating speeds.

The process has also driven innovation, prompting manufacturers to develop cheaper miniature machines that occupy less space. Despite their small footprint, these machines still achieve the quality, accuracy, and precision needed, although they offer additional advantages. For instance, they are more affordable, consume less energy, and are portable, among other advantages. We will elaborate on this below. But first, let’s explore the various micromachining processes.

Types of Micro-Machining Processes and Methods

There are four main types of micro-machining processes, namely:

- Mechanical micro-machining

- Thermal micro-machining

- Chemical and electrochemical micro-machining

- Hybrid micro-machining

Mechanical Micro-Machining

As the name suggests, mechanical micro-machining processes mainly use mechanical forces to remove material from the surface of a workpiece. This means that all grinding, cutting, or abrasive actions involve the interaction of the tools with the workpiece material. Unfortunately, these mechanical interactions lead to tool wear, heat generation (especially when higher cutting forces are used), and various mechanical and thermal effects on the surface. The various mechanical micro-machining methods are discussed below.

1. Micro ultrasonic machining (micro-USM)

Micro-USM utilizes slurry — a mix of water and abrasive materials with particle sizes between 0.1-20 µm — that is propelled onto the workpiece’s surface by a tool vibrating at an ultrasonic frequency of 30-50 kHz and an amplitude of 0.1-15 µm. (It’s worth noting that the minimum frequency in this process is much higher than in conventional USM, while both the amplitude and particle size are significantly lower). The vibrating tool imparts kinetic energy into the abrasives, which are responsible for removing material from a workpiece. Micro-USM fabricates micro-features on hard ceramic materials like composites, glass, and quartz.

2. Micro water jet machining (micro-WJM)

Micro-WJM leverages the kinetic energy of a water jet, which reaches velocities of up to 900 m/s, to remove material from the workpiece surface through generated pressure. Micro-WJM is used for cutting soft materials such as lead, asbestos, rubber, and more, as well as porous materials like wood and corrugated boards.

3. Micro-abrasive jet machining (micro-AJM)

Micro-AJM uses the kinetic energy of loose abrasive particles to remove material in a controlled manner. These particles have a grit size of approximately 50 µm and strike the workpiece at a velocity of 150 to 400 m/s. Micro-AJM is used for deburring, etching, cutting, polishing, and cleaning brittle materials.

4. Micro-focused ion beam machining (micro-FIB)

This method utilizes an ion beam of high intensity and specific diameter to remove material atom by atom. These displaced atoms, ions, or electrons transfer their momentum to bordering ones propagating the material removal. Micro-FIB is performed in a vacuum and uses gallium as the source of liquid metal ions. This method is used to machine micro tools and dies for EDM, diamond micro indenters, micro-surgical tools, fabricate micro end mill cutters, and more.

5. Micro-milling

This mechanical machining process utilizes miniature tools rotating at extremely high speeds to remove unwanted material from the surface of a workpiece. The speeds can range anywhere from 40,000 to 300,000 rpm. The higher the revolutions per minute (rpm), the better the quality of the cut and finish. Additionally, faster speeds reduce the chances of tool breakage while increasing productivity.

6. Micro-turning

Micro-milling is a mechanical machining process that uses miniature tools rotating at extremely high speeds to remove unwanted material from a workpiece’s surface. This way, the cutting tool removes unwanted material from the surface of a rotating workpiece, producing 3D features on a micro-scale.

7. Micro-grinding

Micro-grinding is a process that helps create and finish 3D micro-features. It uses miniature-sized tools with abrasives like cubic boron nitride (CBN) or diamond to remove unwanted material from both hard and brittle workpieces made of aluminum, silicon, and glass. These tools generally have a diameter of less than 1 mm — in other words, the diameter falls within the micrometer range. Notably, the micro-grinding process achieves a low material removal rate (MRR) due to the low depth of cut and high surface finish/quality.

8. Micro-drilling

This mechanical micro-machining process involves using a drill bit with a diameter less than or equal to 1 mm to make a hole inside a workpiece. The resulting hole’s diameter typically ranges from a few to several hundred microns.

Thermal Micro-Machining

This micro-machining process removes material from the surface of a workpiece through ablation (vaporization or melting). Examples of thermal micro-machining methods are discussed below:

1. Micro electrical discharge machining (micro-EDM)

Micro-EDM is a thermal micro-drilling process. It melts and vaporizes material from a workpiece by way of a controlled spark between the anode workpiece and the cathode tool. For this process to work, the workpiece is submerged in a dielectric medium such as air, kerosene, or deionized water, with the workpiece and the tool separated by a small discharge gap ranging from 1 to 5 µm.

Micro-EDM can be used to fabricate features on soft, hard, and high-strength materials. However, it can only be used to machine electrically conductive materials. Compared to conventional EDM, micro-EDM utilizes lower current (up to 5 amps, whereas EDM utilizes at least 10 amps) and voltage (20-180 V compared to EDM’s 40-400 V), and a smaller discharge gap (1-5 µm compared to 10-125 µm in EDM). Thus, micro-EDM contributes to cost savings. This process is used to create micro forceps deployed in neurosurgery, inkjet printer nozzles, precision blanking dies, and more.

SARIX Micro-EDM Machine (source)

2. Micro laser beam machining (micro-LBM)

This method concentrates/focuses a high-energy laser beam on a workpiece, which absorbs the energy and heats up. This heat then melts and vaporizes material, removing it from the surface of the workpiece. Micro-LBM utilizes a higher quality beam than conventional LBM and achieves a better surface finish. This micromachining process is used to prepare silicon wafers, micro-texturing of diamond films, and hard disc drives, as well as drilling micro-holes on polymers for chip packages and circuit boards, among others.

LASERTEC 20 PrecisionTool Machine (source)

3. Micro electron beam machining (micro-EBM)

This process uses a focused beam of high-velocity electrons to thermally displace materials through melting and vaporization.

Chemical and Electrochemical Micro-Machining

Chemical and electrochemical micro-machining processes dissolve materials through chemical or electrochemical means. For this reason, these processes are considered forming and shaping methods. They can machine electrically conductive materials regardless of their roughness, hardness, toughness, or strength. However, they cannot work on chemically inert materials. Additionally, these processes are adversely impacted by passivation effects, which is the formation of a thin protective coat on the surface of the material. Passivation restricts the removal of material; as a result, the accuracy of this micro-machining process deteriorates.

Chemical and electrochemical micro-machining is classified into:

1. Chemical micro-machining

This process removes material through a controlled chemical reaction with a strong acidic or alkaline solution.

2. Electrochemical micro-machining

This is an anodic dissolution process — that is, it dissolves the anode when both the cathode (positive terminal) and anode (negative terminal) are submerged in an electrolyte solution, and a pulsed direct current (DC) is applied.

Hybrid Micro-Machining

Hybrid micro-machining involves the controlled interaction and combination of various micro-machining processes, energy sources, and tools simultaneously (Bijoy). Thus, hybridization usually takes place within the same processing zone and at the same time. Hybrid micromachining is intended to utilize the benefits of each process simultaneously.

This micro-machining process has been shown to aid in the fast and economic fabrication of micro-features. It also helps produce complex shapes with the desired level of accuracy. Plus, it facilitates mass and predictable part production (springer). But that’s not all. Hybrid micro-machining processes can work on materials that are difficult to machine, such as aluminum oxide, Inconel-718, Ti6Al4V (a titanium alloy), polycrystalline diamond (PCD), Zirconia, and more. Moreover, it achieves high surface integrity, quality, accuracy, and material removal rate (MRR). Hybrid micromachining also increases tool life.

The hybrid micromachining process can be categorized into two classes:

1. Combined hybrid micro-machining

It combines two or more processes simultaneously and in a controlled manner, with both processes contributing to material removal. Examples of processes that fall in this category include: electrochemical micro-grinding, electrochemical discharge machining, mechano-chemical polishing, electrochemical arc machining, simultaneous electrical discharge/electrochemical machining (SEDCM)

2. Assisted hybrid micro-machining

This category covers hybridization where only one of the processes removes the material, but additional energy in the form of a magnetic field, vibration, abrasive fluid, or a strong electric field is introduced to aid in material removal. Examples of assisted hybrid micro-machining processes are abrasive electrochemical honing, abrasive electrical discharge machining, vibration-assisted electrical discharge machining, laser-assisted turning, plasma-assisted turning, and electrolytic in-process dressing grinding, among others.

Systems, Tools, and Equipment in Micro-Machining

Micro-Machines and Equipment

Micro-machines come in a wide range. They include:

- Miniature/desktop machines designed for the production of micro-parts

- Large/factory-grade machines that are either adapted to handle micro-components or specifically designed from the ground up to machine micro-parts

Miniature/Desktop Machines

First developed by the Japanese in the 1990s before being picked up by manufacturers in Switzerland and elsewhere around the world, miniature machines are scaled-down systems with a small footprint. They are so small, in fact, that they can fit on a desktop.

One such machine, a turning center from NANOWAVE®, for instance, has a body size of 700 x 500 x 600 mm. Another, the ultra-small milling machine, has an even smaller body size, 414 x 450 x 470 mm. According to the manufacturer, both machines can process small diameter holes of 100 microns or less, meaning they perform micromachining.

Such portable machines offer several advantages, including reductions in initial and operating costs, space, and energy. And what’s even more striking about them is they do not trade off accuracy.

Large/Factory-Grade Machines

Modifying large machines to handle micro-components generally involves scaling down some of the machine parts and tools to ensure they can create micro-features on both large and micro-parts. However, such machines lack certain features that prevent or minimize vibration. It is widely recognized that the impact of vibration increases with a decrease in the diameter of the machined features. Thus, micro-features bear the brunt of even the tiniest of vibrations.

Large machines specifically designed from the ground up include vibration sensors or vibration-damping tools. They also include part handling and fixturing provisions. Additionally, these machines can support computer numerical control (CNC), thus becoming CNC machines with micromachining capabilities.

Examples of factory-grade machines capable of micromachining are:

- Micro-EDM machines such as the SARIX SX200 PULSAR with micro-EDM technology

- CNC micro-milling machines, e.g., Haas’s CM-1 Compact Mill

- Laser micromachining systems such as the LASERTEC PrecisionTool Series from DMG Mori

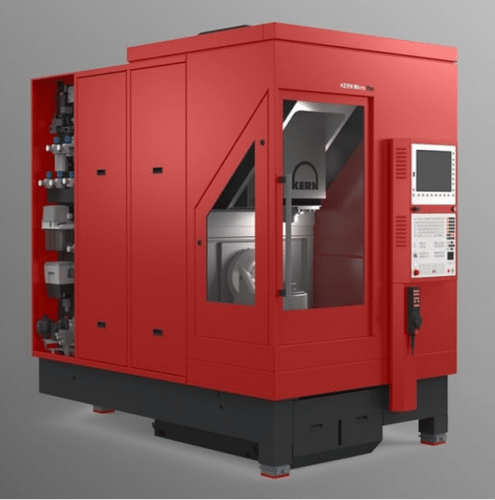

- CNC micro-drilling machines, e.g., the KERN Micro Pro

Kern Micro Pro Micro-Drilling and Micro-Milling Machine (source)

Micro-Tools in Micromachining

Micromachining is synonymous with precision manufacturing. However, the accuracy of the process is dependent on tooling. The size of the tools often dictates the size of the machined features, as the concept of micromachining inherently includes this relationship. Commercially available micro tools are generally made of:

- Diamond, e.g., polycrystalline diamond (PCD) and single crystalline diamond (SCD)

- Tungsten carbide

- High-speed steel

- Cermet

- Cubic boron nitride (CBN)

Diamond tools are used for machining nonferrous material. Additionally, diamond tools coated with chemical vapor deposition (CVD) PCD films are used to machine highly abrasive materials such as graphite. On the other hand, tools made of tungsten carbides take on a broader role as they can handle a wide range of materials, including soft and hardened steel, copper, titanium, aluminum, and stainless steel.

CAD and CAM in Micromachining

Successful micro-machining is impossible without using computer-aided design (CAD) and computer-aided manufacturing (CAM) software, or a combined CAD/CAM system that integrates the capabilities of both. Such systems. In fact, the latter is particularly suited for micro-machining because it minimizes the need for data conversions, which is crucial to maintaining accuracy. This is due to the fact that, unlike separate CAD and CAM systems which require data transfer between software, all data in CAD/CAM systems exist within one ecosystem. These systems should:

- Be capable of working with tight geometric tolerances

- Generate toolpaths based on calculations that abide by the tight tolerances to achieve a high degree of accuracy

- Maintain a constant tool load to prevent breakage of the miniature tools

- Support high-speed machining. This is particularly important in micro-milling because besides promoting faster machining, faster cutting speeds also provide better part quality. Additionally, faster speeds (e.g., 300,000 rpm) also allow for the usage of extremely tiny drills.

Nevertheless, if you are working with CNC machines, CAD files must be prepared for CNC machining. It is worth pointing out that not all CAM or CAD/CAM software is specialized for micro-machining to provide these capabilities. Thus, you cannot just rely on any solution in the market; you might get burnt. Suppose you are looking for a specialized solution that offers micro-machining capabilities. In that case, you can either go for standalone software such as Cimatron or CAD/CAM options that machine manufacturers offer.

Advantages of Micro-Machining

The advantages of micro-machining include:

- Micro-machining results in a superior surface finish

- It aids in the production of parts, both large and small, with miniaturized features for a variety of industries

- The process results in high accuracy and precision

- High-speed spindle rotation promotes greater productivity and repeatability at scale

- Hybrid micro-machining increases efficiency and reduces post-processing, given multiple micro-machining processes can be done within the same workspace

- Micro-machining is capable of working with a variety of materials, including those that are difficult to machine

- This machining method achieves precise dimensions and clean cuts

- Micro-machining is less demanding in terms of its energy requirements than conventional machining, resulting in reduced costs

Disadvantages and Limitations of Micro-Machining

The disadvantages and limitations of micro-machining are:

- Well-established laws on material removal from macro-machining may not apply to micro-machining; this is due to the size effects

- The process is not wholly suitable for machining brittle materials; special approaches should be made whenever you want to micro-machine such materials. Typically, these include maintaining high compressive stresses in the chip formation zone to suppress crack propagation. This is achieved using cutters whose cutting-edge radius is in the nanoscale range. The undeformed chip thickness should also be smaller than the cutting-edge radius.

- When applied to multiphase ductile materials, it causes surface dimple formation

- Micro-machining is affected by burr formation, which increases production cost by up to 9% of the total machining cost, affects the quality of the machined surface, and reduces the part’s capability to meet the desired performance and functionality

- Micro-cutting tools are highly susceptible to deflections and bending, which limit accuracy and precision. This is primarily because these tools have a smaller diameter-to-overhang length ratio, contributing to their reduced strength

- Standalone micro-machining systems may not consistently produce complex shapes with the required accuracy, and they may struggle with mass production of parts with miniature features, making them somewhat unpredictable.

Applications of Micro-Machining

Some applications of micro-machining include:

- Making watches and jewelry

- Machining of microsurgical equipment

- Drilling micro holes for spray nozzles, inkjet nozzles, printed circuit boards, medical equipment, aperture strips for scanning electron microscopes (SEM), pneumatic sensors, high-pressure orifices, micro-pipettes, and satellite/optical apertures

- Manufacture of fuel injectors and nozzles in internal combustion engine-powered vehicles

- Machining of parts and tools for micro-machines

- Machining of extremely hard and wear-resistant materials to create micro dies, molds, and tools

- Manufacture of specialized defense and security components

- Fabrication of dental implants

- Manufacture of micro-sized electrodes using workpieces made of graphite or copper

- Machining of electroless nickel molds for the manufacture of optical pick-up lenses for CD or DVD players

Conclusion

Micro-machining has emerged as a solution to meet the growing demand for parts with micro-features. Besides facilitating miniaturization, this process has also heralded a new era of precision manufacturing. This is thanks to the fact that micro-machining processes achieve a high degree of accuracy, precision, and surface quality. Over the years, innovation has given rise to numerous methods, which are broadly categorized into mechanical, thermal, chemical and electrochemical, and hybrid. These processes are used to fabricate micro-holes, watches and jewelry, dental implants, tools for micro-machines, and more.