Computer Numerical Control (CNC) machines come in different sizes, configurations, and technologies. Nonetheless, what these machines have in common is their use of axes, although the CNC machine axis count still varies from two to five. These axes typically include the linear axes as well as rotary axes. The CNC machine axes dictate the capabilities of the system, from the complexity to the size and shape of the part it can fabricate. The axes also influence the accuracy and precision of the machine.

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

Table of Contents

Basics of CNC Machine Axes

Linear Axes

The Cartesian Coordinate System is a reference system widely used in mathematics and other areas such as computer-aided design (CAD) and manufacturing. It is within the domain of manufacturing that CNC machines fall. This system is based on the concept of three mutually perpendicular axes that intersect at the origin. We refer to these axes as the linear axes, and they include:

- X axis, which is the movement from left to right and vice versa (parallel to the cutting tool)

- Y axis, which is the movement from front to back and vice versa (perpendicular to the cutting tool)

- Z axis, which is the movement from top to bottom and vice versa (perpendicular to the cutting tool)

Rotary Axes

Indeed, we have grown used to the above-mentioned linear axes (X, Y, and Z) from our Math classes. However, when it comes to machining, a new class of axis – the rotary axes – enters the picture. Namely, the A axis, B axis, and C axis, these rotary axes help improve the accuracy and cycle times of fabrication processes. They do so by enabling the cutting tool to reach and work on a few more sides than would have been possible with linear axes. And as will be discussed in greater detail below, this is due to the part’s rotational shift in position.

Rotary axes get their name from their association with rotation. And given that these rotations always happen around one of the three linear axes, the relationship between rotary and linear axes becomes clearer. Typically, this relationship is as follows:

- A axis is the rotation or tilt around the X axis; the A axis is also known as the tilt axis

- B axis is the rotation around the Y axis

- C axis is the rotation around the Z axis

So, what is a rotary axis or rotary axes? The rotary axes relate to rotations around the linear axes by the rotary table that enable the cutting tool to access parts at different angles in order to machine features on the fourth or fifth side of the part.

Understanding Linear and Rotary Axes

You can think of a CNC machine axis as representative of the side from and dimension along which a feature on a workpiece can be machined. However, the term side does not necessarily mean the external face. Instead, and for simplicity, it can also refer to any internal surface that is parallel to the external face of a cube or cuboid.

Starting from the basics, if you encounter a term such as a 2-axis CNC machine, that means the system can only machine features on two sides of a workpiece at a time. As will be detailed below, these machines comprise a combination of two linear axes.

Similarly, if you come across the term 3-axis CNC machine, remember that such a machine performs the cutting action on three sides of the workpiece at a time. These sides will typically be the length (X axis), width (Y axis), and depth (Z axis), with the cutting or drilling tool traveling left to right (and vice versa), front to back (and vice versa), and top to bottom (and vice versa), respectively.

The introduction of the rotary axes gives rise to 4-axis and 5-axis CNC machines, also known as multi-axis machines. But following the same principle introduced above, a 4-axis machine can work on four sides of the part at a time. On the other hand, a 5-axis machine can manipulate and fabricate features on five sides of the part secured in the vise at a time. The multi-axis CNC machines’ additional capabilities, compared to the 2-axis and 3-axis machines, emanate from the ability of the cutting tool and rotary table (bed) to shift positions linearly and rotationally, respectively, which changes the part’s orientation relative to the cutting tool, exposing more sides.

2-Axis CNC Machines

As the name suggests, the 2-axis CNC machine has moving components that travel along two axes. Depending on the type of machine and the work envelope’s orientation (i.e., horizontal or vertical), these two axes can be a combination of the x-axis and y-axis, the x-axis and z-axis, or the y-axis and the z-axis.

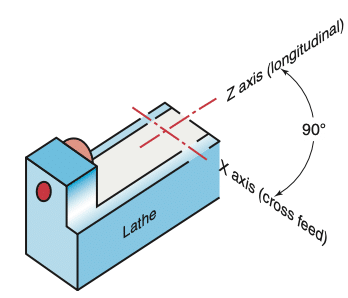

X and Z Axes in CNC Lathe Machine

CNC lathe machines and turning centers fall into this category. They mostly support movement along the x-axis and z-axis. These machines have a number of components, but in this article, we will focus on the chuck, which attaches to the main spindle and holds the workpiece in place, and the cutting tool. The chuck, for its part, rotates around the z-axis. On the other hand, the cutting tool moves along both the x-axis and z-axis.

As far as the cutting tool is concerned, the X axis relates to inward or outward movement. On the other hand, the Z-axis is associated with longitudinal movement (i.e., along the axis around which the chuck rotates). The movement of the cutting tool influences the classification of CNC lathe machines and turning centers as 2-axis CNC machines.

Multiple manufacturers, such as Haas with its ST-series turning centers and Knuth with its Forceturn series, produce and sell high-performance CNC lathe machines and turning centers. Some compact vertical milling machines and high-precision CNC grinding machines also fall into this category of 2-axis CNC machines.

3-Axis CNC Machines

The 3-axis CNC machine configuration is primarily found in CNC milling machines. In these machines, the workpiece is held in place by a vise. The vise, in turn, is fixed to a moving table. Designed to move, the table travels along the X and Y axes, while the drilling or milling tool travels along the Z axis. The combination of these movements means the CNC machine can simultaneously remove materials from the sides that correspond to the length, width, and depth.

This CNC machine axis configuration is ideal for machining simple parts with only a few features. These machines are also ideal for situations where the part does not require a lot of detailing. 3-axis CNC machines can also machine complex parts with numerous features. However, this will likely take longer than it would with systems that have more CNC machine axis configurations. More on this in the below section discussing whether more CNC machine axis configurations are better.

Examples of commercially available 3-axis CNC machines are EC-1600ZT, VF-1, VF-2SS from Haas Automation, the BO 90 CNC and BO T CNC 110 series from Knuth, the VX8 from Huron, and the GENOS M series machines from Okuma.

4-Axis CNC Machines

In 4-axis CNC machines, the axis count is 4. Such machines have the capabilities of a 3-axis machine, i.e., their cutting tool and/or table can move along the X, Y, and Z axes. However, they also support rotation around one of these linear axes. This rotation is thanks to their use of either 4th-axis (single-axis) rotary indexing tables or a 4th-axis swivel head.

Rotary indexing tables have built-in motion systems comprising, among others, fixed motors that link to a fixture plate that rotates around a single axis. They expose a new surface for machining. This process is technically known in manufacturing as indexing. Accordingly, the part clamped onto the fixture plate rotates based on the CNC program generated by the Computer-Aided Manufacturing (CAM) software.

Generally, 4th-axis rotary tables are available in right-hand, left-hand, or bottom configurations, with a bottom-, top-, side-, or back-mounted motor. They also come in different sizes to accommodate different sizes of parts or fixtures. These rotary tables are compatible with CNC machines that have a 4th-axis drive and firmware that supports full 4th-axis operations.

4th-Axis Rotary Table (source)

However, not all machines utilize rotary tables. Some have a swivel head paired with a non-rotating table that is nonetheless capable of traveling along the linear axes. The swivel action of the head introduces 4th-axis rotation. However, this is more accurately described as a tilt because the movement does not constitute a complete 360º rotation. Examples of 4-axis swivel-head machines are the VMX42SWi, VMX60SWi, and VMX84SWi from Hurco.

4-Axis Swivel Head Machine from Hurco (source)

5-Axis CNC Machines

A 5-axis CNC machine has a CNC machine axis count of 5. This number includes the three main linear axes (X, Y, and Z) and any two rotary axes. This means that a 5-axis CNC machine includes the X, Y, and Z linear axes, along with two of the following rotational axes: A, B, or C. The additional two axes in the 5-axis CNC machines originate from two different mechanisms, resulting in two types of 5-axis CNC machines:

- Swivel-rotate-style 5-axis CNC machine

- Trunnion-style 5-axis CNC machine

Swivel-Rotate-Style 5-Axis CNC Machine

Also known as the swivel-head rotary table CNC machines, the swivel-rotate-style 5-axis CNC machines essentially have a swivel head that tilts around the B-axis, with a rotary table that rotates around either the A or C axis. This table supports the full 360º rotation, while the swivel head’s tilt is often less than 130º on either side of the vertical axis. It is worth mentioning that the tilt angle depends on the manufacturer. Hurco SRTi Series swivel-head rotary table machining centers support a maximum tilt of 92º on either side of the vertical axis, for example.

This type of 5-axis CNC machine is ideal for machining heavier parts. It is also less prone to tool interference issues. This is because the rotating table rarely interacts with the cutting tool, regardless of length. Moreover, the swivel-rotate-style machine offers flexibility and versatility. This is because it can machine both heavy and light parts.

Examples of swivel-rotate-style 5-axis CNC machines include the Hurco VMX60SRTi and VMX42SRTi.

Trunnion-Style 5-Axis CNC Machine

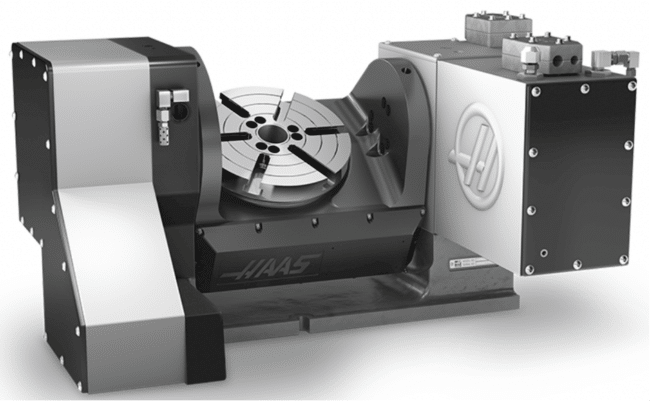

The trunnion-style 5-axis CNC machine introduces the rotary axes via dual-axis rotary tables and indexers. These dual-axis rotary tables orient the part to the cutting tool to take advantage of the cutter’s geometry. As a result, they expose as much as the part’s five sides to the cutter.

These tables tilt around the A or B axis by a specific angle on either side of the vertical axis. This angle typically depends on the manufacturer. CNC machines from Haas Automation support a maximum tilt of 120º each way. In contrast, those from Huron support a maximum of 110º. However, when it comes to the movement around the C axis, all rotary tables and machines support a full 360º rotation.

Haas TR200Y Trunnion-Style Rotary Table (source)

However, these machines have a downside. Due to the rotary table’s continuous rotation and twisting of the part, the risk of tool interference significantly increases. Additionally, the rotation limits the weight of the part that the table can support. In this regard, trunnion-style machines are mostly ideal for machining light to medium-weight parts.

Some examples of Trunnion-Style 5-Axis CNC machines are the VC500i and VCX600iXP from Hurco, the VC-X350from OKK, and the VR series and UMC series machines from Haas.

Multi-Axis CNC Machines

Multi-axis machines are those that have a CNC machine axis count that is greater than three. This means such machines have one or two rotary axes on top of the three linear axes. Compared to conventional CNC machines with two or three linear axes, multi-axis CNC machines offer several advantages:

- Multi-axis CNC machines require fewer setups as their cutting tools can access more sides than conventional machine’s cutters and mills

- The fewer setups translate to less cycle time, i.e., the amount of time spent machining a part with all designed feature

- These machines are more accurate because they eliminate the likelihood of human errors during setup – they have fewer setups and part-loading instances

As with all other machines, multi-axis CNC machines also have a few disadvantages, including:

- They are more expensive to purchase than conventional CNC machines

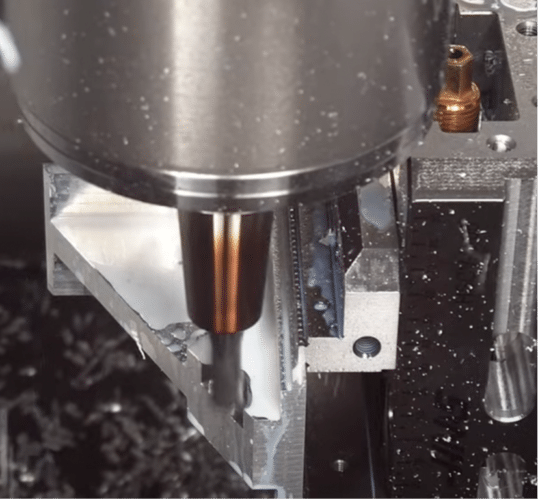

- Multi-axis CNC machines, particularly the trunnion-style 5-axis machines, are prone to collisions between the nose of the spindle of the machine and the side of the rotary table

Image Showing Close Proximity of Spindle Nose to Side of Rotary Table (source)

While the first disadvantage is unavoidable, measures can be taken to prevent the second. Running the machine slowly after loading the part can ensure safety and allow you to monitor the spindle nose’s proximity to the rotary table. If you establish that a collision is more than likely, there are two approaches you can take. First, you can use longer tools. Alternatively, you could attach your tools to an ER collet chuck to elongate them. That said, a few questions linger.

3-Axis CNC Machine vs. 5-Axis CNC Machine

Are higher CNC machine axis counts better? Are multi-axis CNC machines better than conventional CNC machines? To help answer the questions, Haas Automation conducted an analysis. In this analysis, a machinist separately created two identical parts using a 3-axis CNC machine and a 5-axis CNC machine. Though the analysis was not scientific, it offers insights that point to the fact that multi-axis CNC machines are better for machining parts with a high level of complexity.

This is because the use of the 5-axis CNC machine resulted in a 26.6% reduction in the cycle time. This implies that the machinist took less time to machine the part with the 5-axis machine compared to the 3-axis machine. Moreover, the former required just two setups or part loadings, compared to the latter’s five setups. The machinist also had to set the work offset during each setup. This means there were five different sets of work offsets in the 3-axis machine. In contrast, the 5-axis machine just required two. Furthermore, the fewer setups and work offsets because of using the latter dramatically reduced the chances of human error.

Another drawback of the 3-axis CNC machine that the analysis uncovered relates to tooling. The machinist had to constantly change the tool. And he did so even when that tool was required later to machine a feature on the part’s other sides. This added a few minutes to the cycle time. In contrast, the 5-axis machine would complete all machining operations required of the cutter by simply changing the part’s orientation. Only after the cutting tool had finished its job would it be changed. This helped reduce the cycle time.

Are Higher CNC Machine Axis Counts Better?

So, are more CNC machine axis counts better? Yes, they are. In fact, they are preferentially used in high-performance machine shops for pretty much this reason. However, multi-axis CNC machines may not be suitable for all types of machining jobs. This leads us conveniently to the next section, which discusses what goes into choosing the right number of axes.

Choosing the Right Number of Axes

There are numerous factors to consider when choosing a particular CNC machine axis count. These include:

- Cost

- Function

- Part complexity

- Future Plans

Cost

Different CNC machine systems come with varying costs. Naturally, 5-axis CNC machines are more expensive than 3-axis CNC machines. This is because you need to purchase additional accessories, e.g., the trunnion-style rotary table, longer tools, and collet chucks. However, industrial-grade, high-performance 2-axis CNC turning centers can also carry a high price tag. So, the cost may not always be the most crucial factor to consider when choosing the most appropriate CNC machine axis count for your machine shop.

Function

Indeed, Haas Automation established that 5-axis CNC machines are inherently better than 3-axis machines at working on complex parts. However, multi-axis machines are not always ideal for all operations. In machining jobs that require 2-axis CNC machines, such as the CNC lathe or grinder, systems with more CNC machine axis counts will not cut it. Therefore, considering the intended function is crucial when selecting the appropriate number of axes.

Part Complexity

The complexity of a part increases the number of machining operations and tools to be used. And if the machined features are found on multiple sides of the part, then its orientation should be constantly changed. This is done to ensure the cutting tool accesses the different sides. Here, you can use a 3-axis system or a multi-axis system with a CNC machine axis count of 5. However, the former would require additional setups and sets of work offsets, which could compromise accuracy. In contrast, the latter would be a better option thanks to fewer setups and sets of offsets.

Future Plans

It is also important to consider your vision for your machine shop. This should be the case even when your current budget does not allow you to actualize this vision. Do you wish to scale up your operations? Are you looking to eventually reduce operational expenditure by lowering the cycle time? If the answer to both of these questions is an emphatic yes, you could initially purchase a machine whose capabilities can be upgraded later via the purchase of accessories. For instance, you can purchase a 3-axis CNC vertical milling machine that supports the fourth- and fifth-axis drives. You can then enhance your machine shop’s capabilities later by adding a trunnion-style rotary table.

Conclusion

Each CNC machine has a specific CNC machine axis count, depending on whether it employs only linear axes (X, Y, Z), or a combination of linear and rotary axes (A, B, C). While the CNC machine axis configuration is factory-imposed, you can increase the count for some types of machines by purchasing accessories such as a rotary table. All in all, the number of axes found in CNC machines influences their capabilities and functions. For example, while multi-axis machines are optimal for complex parts, 3-axis CNC milling machines are more suitable for simpler operations. Besides the function and part complexity, there are other factors you should consider when choosing the right number of axes. When choosing the right number of axes, consider factors such as function, part complexity, cost, and your machine shop’s future plans.