If you have worked with a handheld router, you understand the difficulty of maintaining accurate cuts. Fortunately, computer numerical control (CNC) has simplified the process, automating what it takes to cut various materials, including wood. CNC machines for woodworking have helped cut the lead time of producing various wooden items. They have also enhanced the precision, safety, and ability to create items with detailed features.

While most, if not all, CNC systems promise to deliver these benefits, the results achieved can differ from one woodworking CNC machine to another. Naturally, this means that some machines are better than others, which is why this article discusses the best CNC machines for woodworking. We will also discuss the factors to consider when choosing a woodworking CNC machine.

Table of Contents

The Best 6 CNC Machines for Woodworking

1. SainSmart Genmitsu 3018-PROVer CNC Router Machine

Size and build: 260mm x 155mm, with 35mm Z-axis travel

Software: Candle, which is based on the open-source GRBL software and runs on the main controller

Ease of Assembly: Easy (Assembly instructions and videos are available; most of the tools you need to assemble the machine are provided)

Starting Price: $269.00

Features of SainSmart Genmitsu CNC Router Machine

On the lower end of the pricing spectrum is the entry-level SainSmart Genmitsu 3018-PROVer woodworking CNC machine. A capable system, the 3018-PROVer is designed for engraving and light cutting tasks. Its gantry can support a laser engraver and a router. And according to some reviews, the machine can even drive a high-speed spindle. Compared to less powerful routers, spindles are better suited for engraving hard-to-cut materials and increasing the speed and accuracy of the machine.

Users report that the SainSmart Genmitsu 30-18-PROVer is easy to assemble. Moreover, they point out that the machine is easy to understand and use, given its excellent design, but fault the Candle software that is shipped with the system. The candle runs on Windows and Linux PCs.

The Candle software loads, edits, saves, and sends G-code to the machine. It can also visualize the cutting action. Once the G-code is sent to the GRBL-based Genmitsu, you can disconnect your computer, and the router will continue cutting with no issue – at this time, all operations are controlled by the controller and its GRBL firmware.

However, some users report that using the software causes the machine to freeze. Instead, they recommend creating the G-code on your computer and subsequently sending the files via a microSD card to the machine’s controller.

Pros of SainSmart Genmitsu CNC Router Machine

- It is affordable

- The woodworking CNC machine has a small footprint

- The router can continue cutting without being connected to a computer, which means your computer doesn’t need to be exposed to dust

- You can easily replace the stock spindle with a bigger and more powerful one

- It uses lead screws, which are more durable and reliable than belts for driving movement along the x and y axes

Cons of SainSmart Genmitsu CNC Router Machine

- The stock clamps are quite small, so they cannot lock down thick materials

- Its recommended Candle software causes lags

2. Maslow Woodworking CNC Machine

Size and build: Variable

Software: Ground Control

Ease of Assembly: Difficult (Building the frame takes at least five hours if you have basic woodworking knowledge. Adding the electronics and installing the software require an additional hour or so.)

Starting Price: $439.00

Features of Maslow Woodworking CNC Machine

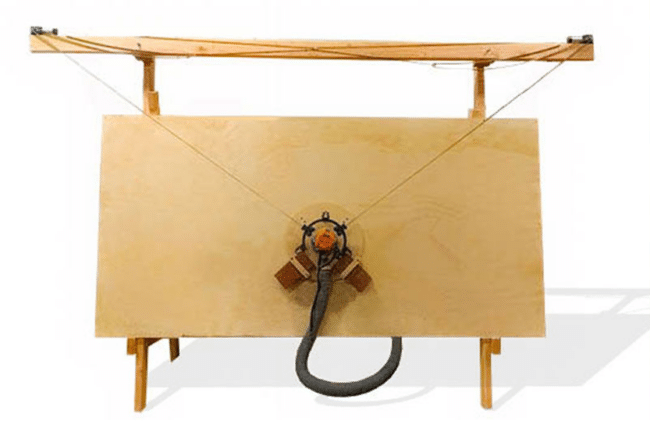

The Maslow CNC Cutting Machine is the most unique woodworking CNC machine on this list. While the other systems are oriented vertically, making vertical cuts, the Maslow machine is oriented horizontally. Created for enthusiasts and hobbyists, this machine is the result of an open-source project that began in 2015. Over the years, and thanks to the contribution of its vibrant community, the Maslow machine has become a reliable cutting solution for large sheets.

The starting price of the Maslow CNC machine is about $439.00. However, this price doesn’t include the materials needed to build the machine’s body and cutting bits. But you may be smitten to find out that you can use it to work on large sheets of wood – as large as 4’ by 8’. And contrary to what you would expect, it does not occupy a large floor space because of its cutting orientation.

As the machine is oriented horizontally, diagonal cables hold the router in place. It is also weighted to maintain contact with the surface of the material. Unlike other woodworking CNC machines that are shipped with all necessary parts for assembly, the Maslow woodworking CNC machine is not. Instead, you have to improvise to build the frame that will anchor the cables and the sheet. The frame can be large enough to accommodate 4’ by 8’ sheets or, according to its makers, it can be smaller; it all depends on your workflow and preferences. The Maslow machine is primarily a 2-axis machine (refer to our comprehensive guide on CNC machine axes for a detailed explanation).

Pros of Maslow Woodworking CNC Machine

- The machine can work on large sheets of wood – as large as 4’ by 8’

- It can also work on smaller sheets

- The Maslow woodworking CNC machine is quite affordable

- It takes up less floor space

Cons of Maslow Woodworking CNC Machine

- Machine setup is quite difficult and time-consuming as you have to make the frames from scratch – it is a DIY machine

- It is slow

3. BobsCNC Quantum CNC Router

Size and build: 24” by 24” with 3.8” Z-axis travel

Software: GRBL firmware on the microcontroller paired with the BobsCNC’s Basic Sender software (installed on a laptop), which sends G-code files to the microcontroller

Ease of Assembly: Difficult – this woodworking CNC machine contains many wooden parts, and assembly can take at least eight hours

Starting Price: $1,280.00

Features of BobsCNC Quantum CNC Router

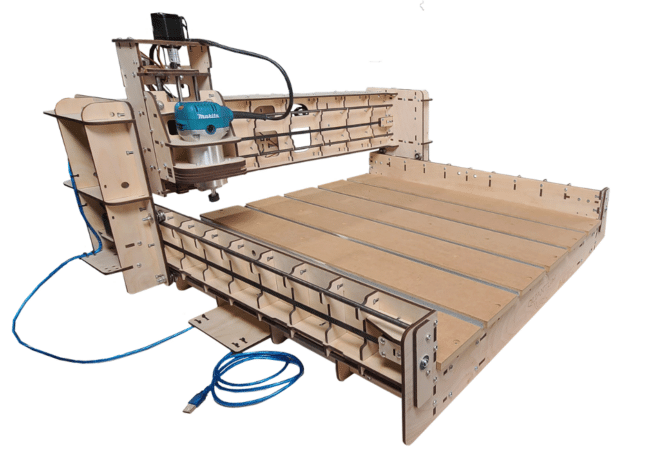

The BobsCNC Quantum CNC Router is a 3-axis desktop machine designed for 3D carving and 2.5D projects. It is suited for making home décor items, signs, and more. Unlike the other woodworking CNC machines on this list, the BobsCNC Quantum machine is made of wood, specifically plywood. The machine consists of numerous parts and flanges that are screwed together to promote rigidity. While the number of parts is beneficial in this regard, it increases the complexity and time taken to assemble the machine.

That said, the cutting action remains unaffected, as it utilizes a Makita router. Belts drive the gantry’s movement along the X and Y axes, while a nut mounted on a lead screw controls movement along the Z axis.

All in all, this wooden woodworking CNC machine has the following features:

- Rigid laser-cut frame

- Self-squaring gantry

- Clamping table with aluminum T-slots

Pros of BobsCNC Quantum CNC Router

- The manufacturer provides excellent assembly instructions

- BobsCNC calibrates the Makita router to the woodworking CNC machine, promoting convenience

Cons of BobsCNC Quantum CNC Router

- The Makita router is loud, with peak noise levels of about 103 dB

- The accuracy of the BobsCNC Quantum woodworking CNC machine is easily impacted by factors such as micro-stepping, bit deflection, lead screw error, belt stretch, and more

4. Axiom Precision Iconic 8 CNC Machine

Size and Build: 24” by 48” with 4” Z-Axis travel

Software: Vetric VCarve Software (recommended)

Ease of Assembly: Varies, depending on whether you purchase the stand along with the machine. If you just purchase the machine, the assembly is easy. Nonetheless, setup and assembly instructions are available online on video and in a written manual.

Starting Price: $5,999.00

Features of Axiom Precision Iconic 8 CNC Machine

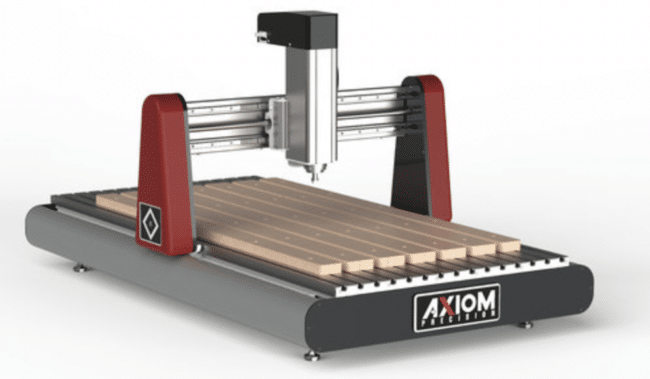

Compared to the more expensive ShopBot Desktop Max, the 3-axis Axiom Precision Iconic 8 CNC Router offers value for money. Not only does it have a larger bed/table size, but it also ships with an optional stand with built-in casters, leveling feet, and a toolbox. It offers accuracy and has been rigorously tested by its manufacturer.

The Precision Iconic 8 is designed for hobbyists. However, this doesn’t diminish its accuracy and ability to maintain precision over repeated use. It uses a high-rigidity extruded aluminum frame. If you are looking for a professional-grade machine from Axiom Precision, you can go with the Axiom Pro V5 Series. It measures 24” by 48” and costs $8,499.00 without the stand.

Some of the Precision Iconic 8’s features include:

- 1.1 HP spindle

- RichAuto B11 Industrial 3-axis controller

- Available stand with built-in casters, leveling feet, and optional toolbox

- Optional customization with accessories such as tooling, dust collection, software, clamping, and much more

- Prismatic guides in all axes

Pros of Axiom Precision Iconic 8 CNC Machine

- The assembly is relatively straightforward, given the availability of instructions

- The machine uses a spindle, which is more powerful and accurate than a router

- It is very stable even when running at a high RPM

Cons of Axiom Precision Iconic 8 CNC Machine

- It cannot be run directly from a laptop or PC

- The Axiom Precision machines with HUST controllers confine you to using the Vetric software, as there is a lack of post-processors for various CAM software in the market

- The Axiom Precision Iconic 8 is quite expensive, considering it is designed for hobbyists. Yet there are cheaper CNC machines for woodworking for this category of people, including the Carbide Shapeoko 4. That said, the Shapeoko 4 uses a router rather than a spindle

5. Phantom SCV 44

Size and build: 4’ by 4’ work area with 9” of Z-axis travel

Software: Phantom CNC’s custom software running on the HD-100 Pendant Controller

Ease of Assembly: Easy – the machine is shipped pre-assembled

Starting Price: $10,950

Features of Phantom SCV 44 Woodworking CNC Machine

The 3-axis Phantom SCV 44 CNC machine is a compact version of Phantom CNC Systems’ larger S and T series. Therefore, it retains most features found in the larger models, features that make it a perfect production-grade woodworking CNC machine. These features include:

- Multi-zone 4’ by 4’ vacuum table

- 6.1 HP air-cooled spindle

- Oil-mist cooling system

- Automatic rollers with 600 pounds of pressure

The Phantom SCV 44 can be compared to the PRO4848 4’ by 4’ CNC router from Avid CNC. However, the latter woodworking CNC machine suffers from rigidity issues, given that the parts that make up its frame are not rigidly fixed. Additionally, it is prone to stepping issues, which misalign the y-axis, substantially affecting the accuracy of the cuts. But even with the flaws, the PRO4848’s price can be as high as $17,305, depending on the configurations. These shortfalls influenced the inclusion of the Phantom SCV 44 in this list of the best CNC machines for woodworking.

Pros of the Phantom SCV 44 Woodworking CNC Machine

- It comes standard with automatic rollers, which work in conjunction with the vacuum table to securely clamp the sheet

- The machine offers easy controls via the handheld pendant control system

Cons of the Phantom SCV 44 Woodworking CNC Machine

- The Phantom SCV 44 machine is heavy, weighing 1,350 lbs. (612 kg)

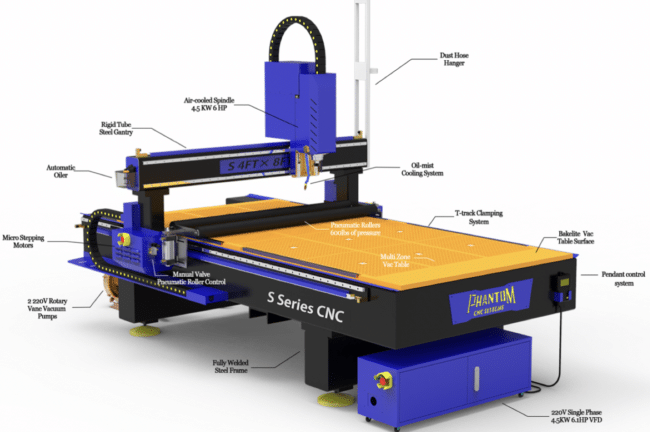

6. Phantom S Series CNC Machine

Size and Build: 4’ by 8’ or 5’ by 10’ stock sizes (although you can request custom sizes) with 8” or 11.8” of Z-axis travel

Software: Phantom CNC’s custom software running on the HD-100 Pendant Controller

Ease of Assembly: Easy – it comes pre-assembled

Starting Price: $20,500

Features of Phantom S Series Woodworking CNC Machine

The 3-axis S Series is an industrial-grade woodworking CNC machine from Phantom CNC Systems. It enables you to perform complex and high-precision operations. It is also capable of running for prolonged periods. Moreover, its automatic oiler feature increases convenience by undertaking some of the machine’s maintenance on your behalf.

The main features of the Phantom S Series include:

- 6.1 HP spindle (6000-18000 RPM)

- Multi-zone vacuum table

- Air and oil-mist cooling

- Automatic oiler

- Automatic pneumatic roller with 600 pounds of pressure

- HD-100 pendant control system

- Accessories such as vacuum pumps and dust collectors (sold separately)

Pros of Phantom S Series Woodworking CNC Machine

- It comes standard with a multi-zone vacuum table that firmly secures the sheet in place

- The Phantom CNC S Series offers high rigidity because it has fully welded steel frames

- This woodworking CNC machine is cheaper than some of its solid frame competitors, e.g., the ShopSabre Pro Series, CAMaster Panther Series, and Laguna Tools’ SmartShop M

- It ships with automatic pneumatic rollers that provide 600 pounds of pressure pressing the sheet to the table – this feature enables you to work on otherwise warped sheets

- Its gantry is gear-driven, which promotes precision

- The machine’s handheld control system makes it easy to control

Cons of Phantom S Series Woodworking CNC Machine

- It’s shipped pre-assembled, which may increase shipping costs due to its weight

- The Phantom S Series woodworking CNC machine is heavy, weight between 2,300 lbs. (1,043 kg) and 2,600 lbs. (1,179 kg)

Factors to Consider When Choosing a CNC Machine for Woodworking

Many of the factors considered when choosing the right CNC machine for your business also apply to woodworking. However, some factors are specific to machines used for woodworking. In this section, we will discuss all of them.

Size

Most enthusiast/hobbyist-grade CNC machines have a small footprint. The footprint increases with the increase in utility. Generally, systems that are used in production must occupy a larger area because they are designed to cut large sheets of wood. They also feature additional components such as vacuum pumps, dust collection units, and pneumatically controlled rollers, just to mention a few. These extra components also occupy additional space. So, it is essential to consider the available space in your workshop whenever you want to purchase a woodworking CNC machine.

Setup or Assembly Time

Some CNC machines come pre-assembled from the factory, while others are shipped in tens of boxes for you, the buyer, to assemble. Putting the various parts together is a time-consuming exercise. It can even take several days, depending on the size of the machine and the number of people taking part in the assembly. This time could otherwise be spent on productive tasks. In a business setup, this adds to the labor cost. Thus, if you are not looking to allocate valuable time to assemble the CNC machine, purchase a machine that is shipped in a pre-assembled/complete state.

Frame and Table Rigidity

Some CNC machine manufacturers produce frames from extruded aluminum. Besides being easy to manufacture, this material makes the CNC machine easy to ship, especially because the manufacturer ships the parts in boxes for the user to assemble. It also has the added advantage of facilitating upgrades. If you later need a larger table, you can simply replace the shorter frame components with longer ones.

However, the lightweight nature of the material, plus the fact that assembly is done using bolts rather than welds, presents a problem: chatter or unwanted vibrations. The entire table vibrates when the spindle is rotating at high RPMs or moving at the maximum supported rapid. These vibrations can be a source of inaccuracy.

To avoid this, select a CNC machine whose parts, including the table, are welded firmly together. This manufacturing approach ensures the machine is rigid enough to resist any vibration. The rigidity improves performance and precision.

Upgradeability

If you are starting out, you may want a machine whose table size you could upscale later. CNC machines, such as the Pro4896 CNC router from Avid CNC, are constructed with upgradability in mind. This machine is built using lightweight material – extruded aluminum, with the various parts pieced together using bolts and screws. Thus, in the event that you want to upgrade the machine to a bigger size, you could simply order longer components that will replace the shorter parts. In contrast, machines whose parts are welded together cannot be upscaled.

Purpose

Do you intend to use the CNC machine for business or as an additional tool in your woodworking hobby? The answer to this question will guide your decision making. Factors typically considered when choosing an ideal system for your business include accuracy, precision, and speed.

In a business setup, you would want a machine that makes products using the shortest lead time. This would come in handy during rapid prototyping. This would necessitate selecting a machine that supports rapid cutting speeds without compromising accuracy or precision. Therefore, this would mean that you would go with an expensive machine that has a large footprint and is gear-driven rather than belt-driven. For instance, the SmartShop series CNC machines from Laguna Tools, whose tables can be up to 5’ by 12’ in size, have a starting price of $39,500.

In contrast, your approach would be vastly different if you were a hobbyist. Naturally, you would be less concerned with the speed of the cuts, the accuracy, or the precision. You would also want a CNC machine that takes up less space. The Maslow CNC machine, for instance, has a starting price of about $439.00.

Budget

There is a woodworking CNC machine for each budget. This is reflected in our list of the best CNC systems for woodworking. Generally, however, the cost depends on the size and features. But the most expensive machine is not necessarily the best. You can find a cheaper option with more features.

Similarly, the least expensive system is not always the worst. This is particularly true if you require a machine for straightforward tasks. Thus, you should also consider other factors besides the cost.

What Items You Will Make

One of the primary considerations to keep in mind when shopping for a woodworking CNC machine is what you plan to use the system for. Some machines excel at engraving, while others are better suited for carving. Similarly, the sort of machine you would use for milling furniture will be different from the ones you would use to carve signs or engrave parts.

Router or Spindle

The spindle vs. router debate is quite common, with many discussing the differences and sometimes attempting to answer the question, which is better? Woodworking will definitely rope you into this debate. This is because the choice between a spindle and a router will significantly impact the quality and quantity of your work – and your wallet. Granted, both are rotary components responsible for rotating the attached cutting tool in order to remove material for a wooden workpiece. However, they differ in how they operate, i.e., their performance and output, as well as their cost.

Spindles are rated for continuous use, while some routers are not. Compared to routers of the same size, they are powerful and quieter, and their speeds are more easily controlled via CNC. These benefits generally make them more expensive. But they outlast CNC routers and thus do not require replacement during the machine’s service life. These characteristics make spindles ideal for use in high-powered industrial machines or professional-grade CNC machines, which are generally costlier. For instance, the SmartShop series CNC machines use a spindle setup rather than a router.

Nature of Control

Some woodworking CNC machines come with a pendant control system. This pendant features a USB port that enables you to send G-code files from computer-aided manufacturing (CAM) software via a USB flash drive. Other machines do not have built-in controllers. Such machines require a constant connection to a computer where the supported software is installed. However, due to the dust generated by woodworking, such machines could expose your computer to dust accumulation. Over time, this dust can clog the computer’s cooling system and lead to overheating.

Broadly, the control method impacts your flexibility at the workstation. A pendant controller offers more flexibility than a PC-controlled system. What we mean by this is that you can easily move the machine without taking into account factors such as the location of a desk where you will place your laptop or desktop computer.

CAD/CAM Software

Manufacturers take different approaches to providing CAD/CAM software. Some, like Carbide, develop and sell software alongside their CNC machines. Others use open-source software to control their machines, while others use handheld pendants. That said, the specific CAD/CAM software that comes with your machine should not be a major concern. After all, the majority of CAD/CAM systems are compatible with most CNC machines.

Conclusion

There are tens – if not hundreds – of CNC machines for woodworking. Each offers several features designed to improve its capabilities. But like in every sector, some machines are better than others. In this article, we have compiled a list of the best woodworking CNC machines across various price ranges. However, it is worth pointing out that this is not a review. Instead, its purpose is to inform, which is why we have also discussed factors to consider when choosing a woodworking CNC machine. These considerations include size, budget, frame rigidity, control method, whether it uses a router or spindle, setup or assembly time, intended use of the machine, among others. In summary, here are some top CNC machines for woodworking, categorized by specific needs:

- Best affordable woodworking CNC machine: SainSmart Genmitsu 3018-PROVer

- Best woodworking CNC machine with an alternative format: Maslow Machine

- Best value-for-money production woodworking CNC machine: Phantom S Series