It can be tempting to think that computer-aided design (CAD) and building information modeling (BIM) are the same. However, they are not, and they should not be used interchangeably.. CAD and BIM are distinct philosophies that emerged at different times in the 20th century. Their inventors created and introduced them to simplify otherwise tedious processes and workflows. Since their introduction, both CAD and BIM have caught on, with professionals in numerous industries integrating them into their workflow and appreciating the resultant improvement in productivity. But the CAD vs BIM debate rages on many years later, with multiple questions arising.

What distinguishes CAD from BIM? What similarities do they share? How can they be integrated? We embarked on a fact-finding mission, utilizing a plethora of resources. The result is this comprehensive CAD vs. BIM article, which answers these queries in great detail. Let’s get started.

Table of Contents

Understanding Computer-Aided Design (CAD)

Engineering drawings existed way before the advent of computers. By some accounts, they have been in use for more than 2000 years. But over time, forward-thinking designers and mathematicians introduced various elements, such as orthographic projections, that improved clarity. Still, designers and engineers made these drawings and related calculations by hand. This often meant they had to simplify certain aspects of their designs.

But engineering designs became complicated as humans embraced grandeur and huge structures and parts with complex features. The need for the technical drawings to be precise and simultaneously communicate all the information about a part or built structure became paramount. Thus, computer-aided design (CAD) emerged to replace hand-drawn diagrams.

By definition, computer-aided design (CAD) is the use of computer systems (software) to create, modify, optimize, and document designs. Broadly speaking, CAD relates to using software to visualize ideas of built facilities or products. The software’s capabilities, however, vary from one developer to another.

For instance, while some are specifically developed to draft 2D drawings, others allow for the creation of both 2D drawings and 3D models. That said, both types of CAD software enable you to perform a number of tasks. You can create a 2D drawing or a 3D model, apply materials and light effects, and document the drawing or model with annotations such as dimensions.

History of CAD

CAD traces its origins back to 1957 when Patrick Hanratty developed PRONTO, which is considered the first CNC programming system. Many consider PRONTO the building block of everything CAD. Numerous CAD tools were developed hence, particularly in the 1960s, leading up to the 1982 release of AutoCAD, the first significant CAD program for the IBM PC. We have discussed previously the in-depth history of CAD, including CAD in the pre-1982 CAD and how CAD has evolved since 1982.

Benefits of CAD

The primary benefits of CAD include:

- CAD software helps designers and engineers make more accurate representations of their ideas

- It lets you easily modify designs to improve the quality

- Modern CAD applications have numerous features and capabilities, including support for geometric modeling as well as parametric modeling, which eases the process of creating extremely complex models

- It eases cost estimation by helping create the bill of quantities

- CAD helps you create documentation of the designs and drawings

- It improves precision and lowers the chances of making errors

- In case of errors, CAD simplifies the process of modifying designs

Applications of CAD

Professionals and students use computer-aided design in the following areas:

- Architectural design for buildings and infrastructure

- Engineering design for infrastructure and buildings

- Design of printed circuit boards (PCB)

- Design documentation

- Video game design: modeling 3D objects that go into video games

- Microprocessor design

- Biomedical engineering design

- Mechanical engineering design

- Aerospace and naval engineering design

- Electrical design

- Fluid mechanics design

Understanding BIM

The next phase of the CAD vs BIM comparison, of course, involves understanding BIM. Like CAD before it, BIM emerged to simplify processes involved in the design, construction, and maintenance phases of a built facility’s lifecycle. Short for Building Information Modeling, BIM is the process of creating, maintaining, using, and exchanging the comprehensive digital representation of a built facility throughout its lifecycle. The representation, known as a building information model, stores all project information. Typically, the model comprises the following:

- Detailed three-dimensional geometry of the building components

- Spatial relationships that relate to zones and spaces

- Geographical information

- A hierarchical project structure

- Schedules

- Semantic information (metadata) such as technical properties, cost, component type, materials, quantities, and relationships between the components and other physical or logical entities

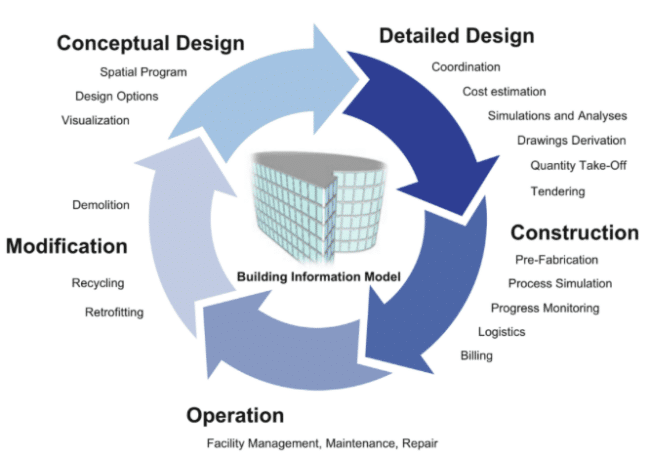

The model is then made available to various stakeholders in the Architecture, Engineering, and Construction (AEC) industry. These stakeholders include owners, facility managers, architects, engineers, fabricators, contractors, and subcontractors. BIM provides an integrated solution that enables professionals to manage construction projects throughout their life cycle. From defining project objectives, through early conceptual and detailed design phases, to the construction phase, long-term operation, and, finally, the end of their useful life.

Lifecycle of a Built Facility (source)

The use of BIM is replacing the traditional way of doing things. Previously, information was handed over to downstream professionals in the form of drawings, either in a digital but limited format or as printed views on paper. However, these drawings contained limited information that computers could not understand. Furthermore, computational methods could only partially interpret and process the information. Relying on drawings as a basis for information flow, therefore, impeded the ability of teams to harness the great potential of information technology. Fortunately, BIM solves this problem.

History of BIM

The BIM philosophy was pioneered by Jonathan Ingram, who is sometimes aptly referred to as the ‘Father of BIM.’ In his book, “Understanding BIM: The Past, Present, and Future,” Ingram documents how he wrote the SONATA system in the early 1980s. SONATA, fulfilling all the criteria for BIM, was the first authentic BIM system. (But the terms Building Information Model and Building Information Modeling would be coined much later.)

SONATA was developed for engineers, architects, and other professionals involved in the planning, design, and construction of buildings. It used a single model, now known as a BIM, to coordinate both graphical and non-graphical of all objects and components that made up a building. Furthermore, it had intelligent capabilities – it could automatically design and modify certain components based on the surrounding conditions of the model. What’s more, combined within the model were other design facilities, including structural steel design, thermal analysis, and more.

Ingram, together with a group that had become part of the SONATA project, then went on to write REfLEX between 1992 and 1993. REfLEX incorporated all of SONATA’s functionalities but added some new capabilities, including a modeler and a renderer. REfLEX was later sold to PTC, Inc. (then Parametric Technology Corporation) in 1996 and marketed thereafter as ProReflex. But in 1997, PTC stopped the development of the software and subsequently gave a non-exclusive development license to several of its employees, the founders of Revit. Hence, SONATA and REfLEX set the stage for the BIM as we understand it today.

Benefits of BIM

The primary benefits of BIM include:

- BIM supplants physical drawings by storing, maintaining, and facilitating the exchange of information through comprehensive digital representations

- It facilitates the seamless integration of simulations, analyses, and computations, which aid in decision making

- BIM facilitates clash detection: By allowing visualization, it enables professionals to detect conflicts, clashes, and interferences, thus helping them avoid mistakes during the design and construction phases.

- It enables consistency of vertical and horizontal sections of technical drawings, given most of these drawings are directly derived from the model

- It reduces document errors and omissions (by up to 52%)

- BIM minimizes reworks (by up to 48%)

- Building information modeling results in cost reduction and control throughout the project life cycle because it provides predictable information about materials, schedules, cost, and quantities. This way, it also improves the accuracy in the tendering and bidding process

- Cloud BIM enables access to site information anytime and from anywhere

- BIM improves information flow, given all participants in a project already know and clearly understand their responsibilities

- It semi-automatically checks compliance with codes and regulations

- BIM fosters collaboration by enabling cohesive teamwork

Applications of BIM

As mentioned earlier, BIM is applicable throughout the entire project lifecycle, spanning design, engineering, construction, operation, and modification. Thus, we will look at how BIM is applied in each of these phases.

BIM in the Design and Engineering Phase

The application of BIM in the design development and engineering phase involves the following use cases:

- Technical visualization of 3D models

- Coordination of specialist disciplines by merging their respective discipline models into a single coordination model

- Derivation of technical drawings from the model; such drawings only show major parts or sections of design or construction drawings

- Use of BIM data as input for simulation and analysis tools

- Cost estimation using BIM-based quantity data

- Creation of Bill of Quantities from BIM-based quantity data for tendering construction works

- Linking individual components of the BIM model with the corresponding processes of the construction schedule, a process known as 4D modeling

- Updating the 4D model to reflect and monitor the progress of the project

- Linking the 4D model with costs for purchasing and/or fabricating the corresponding building components and monitoring the cost progress, a process known as 5D modeling

- Billing and controlling based on monitoring the progress of the BIM model

- Monitoring and documenting construction defects and tracking their removal

BIM in the Construction Phase

Contractors and subcontractors also use BIM to prepare and execute the actual construction of a built facility. It is applied in the following ways:

- The digital model, submitted as part of the tendering process, helps contractors determine the service and cost

- The model also facilitates precise billing at all stages of the construction

- A 4D building information model helps construction professionals to validate construction sequence

- Detection of potential spatial collisions

- Organization of site logistics (using the 4D model)

- Simulation of the cost development over time (using the 5D model)

- Invoicing of construction work

BIM in the Operation Phase

Typically, the design team hands over the BIM information to the client or owner once they complete supervising the construction. At this stage, the BIM includes all design data as well as relevant information from the construction phase. This digital information is then fed into facility or asset management systems for operations and maintenance. We group the BIM information required in the operation phase into two categories that make up the 6th and 7th dimensions:

- 6D BIM contains sustainability and lifecycle information. This information helps safeguard the energy efficiency and sustainability of a built facility. It is generated through energy analysis, sustainable element tracking, and Leadership in Energy and Environmental Design (LEED) tracking.

- 7D BIM contains holistic facility management information. This information relates to data about the installed devices, including their maintenance cycles and warranty conditions, which are particularly important. It is worth noting that the BIM should be updated with maintenance records or any changes made to the facility whenever they occur. This data proves useful at the end of the facility’s lifecycle, especially during demolition.

Key Differences between CAD and BIM

Computer-aided design and building information modeling differ in many ways. From how they are used and the industries in which they are used to the scope of information stored and the file sizes. The section below summarizes

CAD vs BIM: Difference Summary

|

|

CAD |

BIM |

|

Users |

It is used by engineers, architects, and designers |

It is used by engineers, architects, and designers, as well as contractors, subcontractors, fabricators, clients/owners, facility managers, and demolition experts |

|

Collaboration |

CAD systems are not suited for collaboration |

BIM systems are suited for collaboration |

|

Use case |

CAD use is restricted to the design development phase |

BIM use extends throughout the entire lifecycle of a built facility |

|

Industry |

CAD is used in numerous industries, including AEC, manufacturing, product design, infrastructure development, electrical and electronics, bio-medical, gaming, chemical, and more |

BIM is primarily used in the AEC industry |

|

Scope of Information Stored |

It is restricted to 2D and 3D data, i.e., the design aspect |

It encompasses both 2D and 3D data as well as 4D (time/schedule aspect), 5D (cost aspect), 6D (energy efficiency and sustainability information), and 7D (holistic facility management information) data |

|

History |

The CAD philosophy was invented in 1957, with the first CAD systems developed in the 1960s |

The BIM philosophy was invented in the early 1980s with the creation of SONATA |

|

File Sizes |

CAD file sizes can be anywhere between a few kilobytes (KBs) to a few megabytes (MBs) |

BIM files can be huge, from a few hundred MBs to a few gigabytes (GBs) |

|

Detail Retention |

CAD models are only capable of presenting a highly detailed image at a particular zoom level |

Building information models maintain the same level of detail regardless of whether they are zoomed in or out, expanded, or contracted |

|

Independence |

CAD can be used as part of BIM, but the addition of CAD models into a BIM system can, at times, give rise to problems when you need to zoom in or out due to the differences in their ability to retain details |

BIM cannot be used as part of CAD; it can be used independently of CAD |

|

File Formats |

CAD File formats include DWG, DXF, CATPart, prt, asm, prt, sldprt, sldasm |

BIM file formats include RVT, NWD, DWG, DXF, IFC, and COBie |

Key Similarities between CAD and BIM

The CAD vs BIM discussion is not limited to differences. It also encompasses similarities, which brings us to the question we had asked earlier: Are there similarities between BIM and CAD? Yes, there are numerous parallels or similarities between CAD and BIM, including:

- Cloud Computing: both CAD and BIM incorporate cloud computing. Developers, including Autodesk, Trimble, and PTC have rolled out cloud-based CAD software such as AutoCAD Web, Fusion 360, and Sketchup for Web. Likewise, BIM developers such as Autodesk and Graphisoft have created cloud-based BIM solutions like BIMcloud and Revit Cloud Worksharing.

- Both CAD and BIM support 2D drafting and 3D modeling

- Shared file formats: some file formats, such as DWG and DXF, work with both CAD and BIM drawings

- Productivity and efficiency: Both BIM and CAD software improve the efficiency and productivity of professionals

- Design and documentation: CAD and BIM systems both enable professionals to create designs and documentation

The Process of Integrating CAD and BIM

There may be a time when you wish to integrate BIM with CAD or vice versa to reap the benefits both philosophies and systems offer. For instance, suppose you want to model using BIM software, yet you have an architectural floor plan or a structural drawing previously created using CAD software. In such a case, you will need to connect the CAD software with the BIM software, a process known as integration.

How to Integrate CAD and BIM

Within the context of CAD vs BIM debate, there are other techniques you can use to integrate software, namely:

- File Formats

- Application programming interfaces (APIs)

- Add-ins

File Formats

One of the most fundamental ways of integrating CAD with BIM is to use shared or compatible file formats. Though developed by different developers, programs used in related industries are usually architected to support a few similar file formats. As evident from the CAD vs BIM comparison table above, and as highlighted in the section discussing similarities, certain file formats are supported by both CAD and BIM software. The shared file formats include DWG and DXF.

The shared file formats support the following workflow: you can create your architectural floor plans or structural designs in AutoCAD and save them as DXF or DWG files. You can then import these files when you want to work on a model using BIM software such as Vectorworks, Revit, or ArchiCAD. Revit goes a step further by allowing you to link the CAD file. According to Autodesk, whenever the original linked file is modified, the changes will automatically reflect in the Revit workspace when you reload the project.

Similarly, you can save a BIM model as a DWG file and later open it with CAD software. You can also save the CAD drawing in a BIM format like IFC. Though primarily a BIM format, IFC is supported by some CAD software, such as AutoCAD Architecture.

However, it’s essential to remember that converting CAD files to BIM carries the risk of partial or complete data loss. This is especially true when working with CAD files that have stored rich data sets. The problem is further compounded if you use software from different developers. To mitigate against this risk, it is advisable to use software from the same developer. For instance, you can use AutoCAD and Revit.

Application Programming Interfaces

Application programming interfaces (APIs) enable the sharing of design data between BIM and CAD software. They eliminate the need to import and export entire design models. Examples of APIs that enable you to integrate CAD with BIM – and vice versa – include Autodesk’s Data Exchange Connectors, available as plug-ins, and ArchiCAD Connector, developed by Speckle Systems.

Add-Ins

Add-ins are programs designed to be used with specific larger programs, such as CAD or BIM software. The add-ins serve a particular function, which depends on how they are configured. Some are designed to export specific components of a model or CAD drawing to formats that are not natively supported by the larger software. IFCout is an excellent example of this type of add-in. It lets you export components of a model to IFC format, a non-proprietary BIM file format.

Others, such as Autodesk BIM 360 Glue, are cloud-based tools. BIM 360 Glue is a cloud-based BIM management and collaboration tool that supports more than 50 different industry formats. It is designed to integrate directly with multiple Autodesk software, adding BIM and collaboration capabilities to CAD software such as AutoCAD.

Conclusion

Computer-aided design (CAD) and building information modeling (BIM) are distinct philosophies with several shared characteristics. The philosophies are integrated into computer systems, birthing CAD software and BIM systems. Both BIM and CAD systems ease the process of designing and documenting. They also enhance productivity and improve precision. However, as emphasized in the CAD vs BIM comparison table, the differences significantly outweigh the similarities. The primary difference is the fact that BIM is based on data-rich models, which store numerous types of data that are used by professionals throughout the lifecycle of a built facility. Contrarily, CAD only stores design-related data. That said, there comes a time when design professionals need to capitalize on the benefits of both CAD and BIM. In such scenarios, they can integrate CAD with BIM using compatible file formats, APIs, or add-ins.