If you have used any 3D CAD modeling software lately, you may have undertaken a few operations involving either parametric modeling or direct modeling. But if you are new to the modeling world and, by extension, the world of CAD and only have a rough idea – or none – of these design paradigms, do not fret, as you are in the right place. This article will discuss each of these concepts, detailing how parametric modeling compares to direct modeling.

Table of Contents

What is Parametric Modeling?

Parametric modeling is a design paradigm that involves stipulating dimensions that define the geometry of a part and subsequently establishing and outlining the relations between the dimensions both across and within the part. Thus, the entire model will be automatically modified or rebuilt whenever one or more dimension values are changed. This captures the design intent. After all, all the dimensions have a predefined relationship.

Generally, the design intent in parametric modeling is captured by:

- The relationship between the base block (unmodified block or parent) and any newly introduced entity (child), also known as a parent-child relationship

- Parametric relationship between dimensions

- Relations within the sketch profile (sketch relations)

This paradigm is sometimes also known as feature-based parametric modeling. This is for a good reason. You see, a conventional 3D model comprises primitive geometric entities such as curves and points and solid primitives such as cylinders, cones, spheres, boxes, and wedges. Dealing with these primitives is less desirable, especially when designing complex parts. In fact, design professionals rarely think along the lines of these primitives whenever they are creating a part. Instead, they think about features, like faces and edges, that correspond to the model’s physical entities.

How Parametric Modeling Works

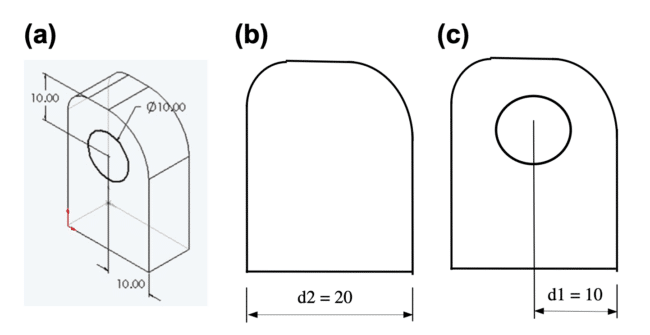

Figure 1: Parametric Modeling Example (source)

To better understand how parametric modeling works, let us consider figure 1 above. A designer wants the hole in the block shown (figure 1a) to remain centered even when the length of the block changes. To capture this design intent, the engineer must create a sketch profile of the block (figure 1b) with dimension d2 as the design variable.

Next, the hole must then be placed on the sketch profile, as shown in figure 1c. This time, however, the designer must specify the relationship between the center of the hole and dimension d2. Given the hole must remain centered even if the length is changed, the following relation must be stipulated, d1 (distance of the center of the hole from one edge) should be equal to half d2. Again, this can be simplified as d1 = 0.5d2.

Based on the discussion above, parametric modeling is also known as procedural modeling, history-based parametric modeling, or unidirectional modeling. This is because for d1 to be defined, d2 must be defined first. Thus, d1 is dependent on d2. As a result, the solution to the equation must be done sequentially.

Generally, parametric modeling requires design professionals to anticipate design changes (think ahead) and consequently define features with this in mind. It also mandates them to add parametric relations to sketch profiles. To boost this process, the software creates a history tree that contains all the sequences of features or changes generated by the user using the predefined relations. In addition, it stores data associated with any modification to the geometry.

Benefits of Parametric Modeling

The advantages of parametric modeling include the following:

- It enables design automation because every aspect of the design is stored in a history tree

- Parametric modeling promotes and simplifies the creation of family-driven or platform-based products, e.g., shelves or tools that vary in size but are based on the same platform

Disadvantages of Parametric Modeling

The disadvantages of parametric modeling include:

- Capturing design intent in complex models is not always straightforward as it requires considerable effort from the designer, planning, and careful implementation

- Parametric modeling tools are difficult to use

- The parametric design process can be slow

- Parametric modeling is not flexible, as the designer must always consider the relations between dimensions

- It requires a steep learning curve

- A model created in software A cannot be opened or used in software B because the importation does not include the history tree

- Models can become disorganized if the designer does not follow a logical sequence

- The computation required to regenerate the model increases as the number of features in the history tree grows, which can slow down the workflow

Parametric Modeling Software

Parametric modeling is popular and has been implemented in equal measure by developers of most of the 3D modeling software in the market. From Onshape, CATIA, FreeCAD, and SolidWorks to PTC Creo, Siemens NX, Solid Edge, and Autodesk Inventor.

1. Creo Design and Creo Parametric

PTC Creo was the first to market with parametric modeling capabilities when it launched as Pro/Engineer back in 1988. In 2011, PTC Inc. renamed Pro/Engineer to Creo and created different software products. What came of the rebrand were, among others, Creo Parametric, Creo Design, and, as we will discuss below, Creo Direct.

Creo Design is a powerful, all-encompassing software with industry-standard 3D CAD capabilities. These include parametric modeling and surfacing, 3D part and assembly design, sheet metal design, additive manufacturing, augmented reality, mechanism design, and automatic 2D drawing creation, just to mention a few.

On the other hand, Creo Parametric is an advanced 3D modeling software with capabilities like additive manufacturing, generative design, augmented reality, smart connected design, model-based definition, and more. In addition to offering parametric modeling capabilities, it supports direct modeling to a certain degree. As highlighted below, it is an example of a hybrid system.

2. SolidWorks

SolidWorks’ parametric modeling allows users to define parameters for a 3D model within a history or feature tree known as FeatureManager Design Tree. Generally, SolidWorks then automatically enters these parameters into equations that it then uses to represent mathematical relationships between two or more dimensions in assemblies or parts. The relationships between dimensions can also be defined using dimension names and measurements, other equations, mathematical functions, and file properties.

3. CATIA

CATIA offers parametric modeling capabilities through a number of options. The first, which is parametric modeling using CATIA V5, works by automatically creating intrinsic parameters as the user creates geometries and features. Alternatively, the user can create user-defined parameters that then control the dimensions. In addition, the software allows users to utilize formulas to define relationships between parameters and geometries.

In addition, the parameters can be defined in a CATIA design table, creating different configurations of the same model. For instance, if a model calls for five cylinders with different thicknesses and diameters, the design table is created, and all these measurements are entered. Thereafter, whenever a given configuration is selected, CATIA generates a variation of the cylinder.

Secondly, users can use CATIA | SFE CONCEPT, which allows for the implicit creation and modification of parametric surface models. Others include the ParaMagic plugin for CATIA’s MagicDraw product.

4. Autodesk Inventor

Autodesk Inventor’s parametric modeling captures the design intent in history trees that stores all features as well as Boolean relations between them. The tree also includes the various steps the user took to create the model. As a result, previous features and definitions of the model can be used to regenerate the model whenever a new entity is added.

Furthermore, whenever a user creates a dimension, Inventor automatically regards it as a parameter for the model. The parameters can be used in equations to create new parameters. To put it simply, Inventor uses parametric equations to define the relationships between parameters.

5. Onshape

Onshape is available as a software-as-a-service, accessible via a web browser. This means you must have an internet connection to use the software. Though the software is a relatively new entrant in the CAD space, having launched in the early 2010s, it still packs a punch. Over the years, the developer has fundamentally improved parametric modeling within the software.

Parametric modeling with Onshape allows users to create multiple parts within a single design space. This means common features and inter-part relationships are built in one place. As a result, these parts share the same parametric history, meaning the users do not have to import or open other files whenever they wish to add the parts to an assembly.

Additionally, like SolidWorks, Onshape allows users to create different configurations of the same product. Furthermore, being a cloud-based app, Onshape allows modelers to create in-context relationships without worrying about the complexity of updating a part relative to an out-of-date assembly. The software achieves this through robust database architecture that updates all related files.

More on this in our discussion of the best parametric modeling software products today.

While parametric modeling is as powerful as it is popular and mainstream, it still competes with the relatively newer direct modeling technique for the attention of many a design professional.

What is Direct Modeling?

Direct modeling involves the creation of a model by simply manipulating its geometry. Generally, it is based on how the boundaries, namely the faces, edges, and other features, define or represent the model. As such, all the design professional has to do is pull or push these boundary elements to achieve a given shape, akin to working with clay. However, this time, instead of using hands to mold the clay, the designer just clicks the mouse cursor and moves the geometry as they wish.

In direct modeling, the 3D modeling software does not store the sequence of features or geometry creation. This means this modeling paradigm does not involve the creation of a history tree. Additionally, the designer does not have to define constraints, use parameters to represent the design intent, or provide feature-based information. Overall, the lack of these attributes makes direct modeling faster. This subsequently increases productivity and reduces development costs and design times. In fact, designers can easily use direct modeling to edit, modify, and repurpose solid models, something that is not possible with parametric modeling.

Advantages of Direct Modeling

The advantages of direct modeling are:

- A user can cut and paste elements from an existing design and begin building an entirely new model

- Direct modeling is intuitive and easy to learn

- It is easy to use as it eliminates the need to understand all constraints, meaning it simplifies the process of creating and modifying simple geometries

- This design paradigm promotes rapid iteration and prototyping as the designs can be altered easily

- Direct modeling saves time and money

- It boosts productivity

- It protects CAD models, which are assets to companies, by allowing designers to change a model without worrying about breaking it

- Direct modeling is ideal for one-off designs

- It simplifies the process of making unexpected or late changes in the design process

- It exhibits greater interoperability because files can be exported and imported from one software to another without loss of design information

Disadvantages of Direct Modeling

Direct modeling is disadvantageous in the following ways:

- It is sometimes unpredictable because editing the dimensions does not always yield a predictable result

- Direct modeling is relatively newer than parametric modeling, meaning most experienced CAD modelers are not used to it

Direct Modeling Software

1. Creo Direct

Like Creo Parametric above, Creo Direct is a dedicated direct modeling software. As a standalone software that is only meant for direct modeling, it is easy to use, intuitive, and flexible. It enables users to achieve faster design cycles, especially because it can allow more users to access and use the 3D CAD data. Creo Direct, therefore, promotes collaboration. It is noteworthy, however, that Creo Direct uses direct modeling alongside a history tree, but it hides the tree from the user.

2. Shapr3D

Shapr3D primarily uses direct modeling to create 3D models. It is based on Siemens’ Parasolid® geometric kernel, which underlies the workings of Solid Edge and NX. The Parasolid kernel supports a number of 3D geometric modeling techniques, one of which is direct modeling, as well as graphical and rendering support.

3. BricsCAD

Developed by Bricsys, BricsCAD is a 2D and 3D CAD software that supports dedicated direct modeling. Do note, however, that, unlike Shapr3D, which is primarily a direct modeling software, BricsCAD also supports parametric modeling. That said, its direct modeling commands, which include rotate, chamfer, fillet, deform, stitch, thicken, and push and pull, enable the creation of both solid and surface geometry. These commands are available in various packages, including BIM, Pro, Mechanical, and Ultimate, each of which has its own BricsCAD pricing.

4. Fusion 360

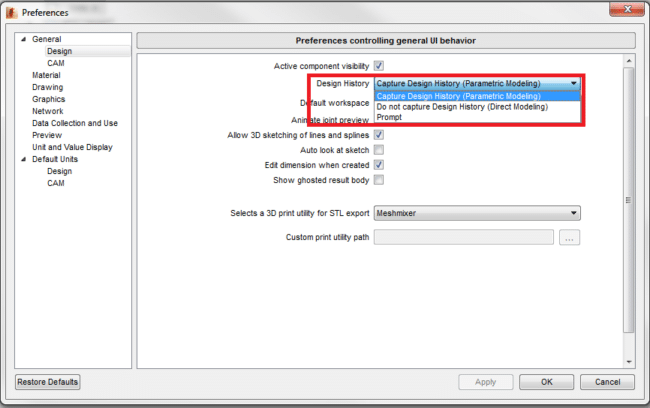

Indeed, Fusion 360 supports both parametric and direct modeling. However, it allows users to easily switch between the two by simply enabling or disabling the software’s ability to capture design history. Unlike other software products that combine parametric and direct modeling capabilities within the same space, Fusion 360 does not. Upon choosing the ‘Do not capture Design History’ option, the software shifts all workflow to the direct modeling workflow. For instance, it does not store any changes to the model in a history tree. As a result, direct modeling with Fusion 360 is fast, straightforward, and offers flexibility.

Figure 2: Autodesk Fusion 360 Preferences Dialog Box (source)

How do Parametric Modeling and Direct Modeling Compare?

In this section, we will use several design aspects to compare parametric modeling to direct modeling. The table below summarizes how these two modeling paradigms differ.

|

|

Parametric Modeling |

Direct Modeling |

|

Pre-planning |

It requires pre-planning of a modeling strategy |

It does not require the pre-planning of a modeling strategy |

|

Nature of geometry manipulation |

Parametric modeling involves indirect manipulation of model geometry |

Direct modeling entails direct manipulation of model geometry |

|

Ideal designs/models |

It is perfect for the design of family-driven or platform-based products |

It is ideal for one-off designs or models |

|

Efficiency |

It features a less efficient way of changing the dimension – i.e., defining the relations |

It features a more efficient way of altering the dimensions – i.e., pushing and pulling |

|

Interoperability |

The parametric modeling approach exhibits less interoperability because importing or exporting files omits the history tree |

The direct modeling approach has greater interoperability as files can be exported and imported without loss of information |

|

Learning curve |

It has a steeper learning curve |

It is easy to learn |

|

Ease of use |

Parametric modeling tools are not easy to use, are inflexible, and slow because the designer must consider relations between features and geometries |

Direct modeling tools are easy to use, flexible, and slow, as they are based on the principle of pushing and pulling |

|

Design Intent |

Parametric modeling requires the designer to have a design intent as the paradigm is based on relationships between features and dimensions |

In direct modeling, the modeler must not have a design intent, as the models are not based on relationships |

|

Ease of updates |

The designs of parametric models can only be changed by designers who are knowledgeable about the associated history trees; thus, they cannot be altered or updated by any party |

The models created using this paradigm can be changed on the fly |

Which Modeling Method is Right for You?

You may have wondered which modeling method suits you as a design professional. To help you out, we look at several factors you should consider:

1. Collaboration Needs

Are you part of a team wherein each modeler has their preferred software, yet you must collaborate by modifying aspects of the models? In such a case, direct modeling should be your go-to paradigm. Given that it does not involve the use of history trees to capture the design intent, this paradigm promotes interoperability. Thus, a model created and saved using software A can be imported and modified using software B without losing vital information.

2. Design Complexity and Sophistication

Parametric modeling is preferred when creating complex models, while direct modeling is ideal for simple, one-off designs. However, remember that the former requires greater planning and effort to create a parametric model.

3. Learning Curve

If you are a beginner, we recommend choosing direct modeling. This is because it is easy to learn and use. Moreover, it is flexible and does not require considerable effort or planning to achieve a desired solid model. Thus, direct modeling is perfect for workflows that do not require modelers to dedicate a lot of resources – time and money.

4. Ease of Use and Workflow

If you are looking for a design paradigm that will not require a lot of planning; one that is straightforward and a tad simplistic, consider the direct modeling paradigm. However, if you prefer dedicating a lot of effort into understanding your model before you can even begin the modeling process, parametric modeling is exactly what you are looking for. It enables you to capture your design intent and define relationships between dimensions and other parameters.

5. Level of Design Iteration and Changes

If you foresee that the model will undergo a lot of changes throughout the design process and may be worked on by new modelers, consider choosing direct modeling. This will simplify the updates by eliminating the need to understand the history tree. On the other hand, if the design iterations will be minimal, consider using parametric modeling.

Hybrid Systems

From the discussion above, it is clear that direct modeling is more advantageous than parametric modeling. But this does not mean that the latter does not have its own strengths. In recognizing the strengths of each of these modeling paradigms, software developers such as Dassault Systèmes, PTC Inc., and Autodesk are, in fact, increasingly creating hybrid systems that merge the capabilities of the history-based modeling approach with the direct modeling approach. This has resulted in the varied implementation of the paradigms. Such software can help you, especially if you are undecided on what to choose between parametric and direct modeling.

Examples of hybrid systems include:

1. Siemens NX and Solid Edge

Siemens NX and Solid Edge enable users to change the geometry of models by moving the mouse or editing the dimensions. The software then preserves the design intent using a unique technology known as synchronous technology, which is nothing similar to the history tree. This way, these applications sidestep the problems that arise whenever software developers implement direct modeling as part of a history tree. Thus, a designer can modify complex 3D models without knowing the relationships and dependencies or how the model was initially constructed.

2. SolidWorks

SolidWorks includes intelligent features that convert non-native imported geometry into intelligent native features that can then be manipulated directly or parametrically. The former can be accomplished using built-in direct modeling tools aptly named Direct Model Editing. However, unlike Creo Direct, which is primarily dedicated to direct modeling, SolidWorks’ tool is simply a feature-based parametric modeling tool. This tool lets users perform direct editing using such functions as drag, push, copy, split, replace, offset, and more. The software then adds the edited features to a model tree.

3. Autodesk Inventor

Autodesk Inventor is primarily a parametric software. Still, it allows users to use direct modeling techniques to scale, resize, rotate, delete, and move geometries. It is noteworthy, however, that this paradigm is mostly used with imported geometries rather than native ones. Autodesk incorporates direct modeling into Inventor to help modelers make edits fast. Users can use the drag handles or the dynamic input to make the changes regardless of the complexity of the part or assembly. In this way, Inventor promotes collaboration.

4. CATIA

CATIA uses a free modeling approach. Although this approach looks similar to direct modeling, it takes a declarative route, with the modeler required to declare the specification to promote precision and capture the design intent. Other than that, CATIA’s system is similar to SolidWorks.

Conclusion

Parametric modeling is a paradigm that requires a modeler to use relationships between features and dimensions to capture their design intent. It mandates the dedication of effort and time to create just a single model. On the other hand, direct modeling uses a push-and-pull approach to building and editing models. It is simple, easy to use and learn, and saves time and money. Over the years, however, software developers have merged the capabilities of both paradigms to create hybrid systems. Still, parametric modeling and direct modeling can exist in isolation, begging the question: which should you use? This article has detailed four factors you should consider when choosing between the two paradigms.

That said, we recommend practicing with each of these paradigms to determine what tickles your fancy. Indeed, if you are a seasoned modeler, you will likely go with parametric modeling. But this does not mean you cannot apply direct modeling in certain aspects of your workflow. In fact, you will likely appreciate the additional advantages of the latter, which can draw you even closer to this relatively newer modeling approach. The same goes for modelers who are not used to parametric modeling. By giving it a try, you might realize it is not as complicated as many set it out to be. This can be particularly true if you use software with which you already have experience.